The Shift from Manual Labor to Automated Extraction

For decades, sugarcane juice extraction was a labor-intensive process requiring significant physical effort and manual cane preparation. Today, commercial sugarcane juicers have transformed this workflow, allowing businesses to scale production without increasing labor costs. The ease of use in modern machines is not accidental; it is the result of precise engineering focused on torque, safety, and hygiene.

For B2B buyers—whether sourcing for a beverage chain, a hospitality group, or a distribution network—understanding the mechanisms that make these machines user-friendly is critical. It ensures you select equipment that minimizes operator training time while maximizing output. If you are currently evaluating your options, you might want to review our guide on How to Choose a Sugarcane Juice Machine? to understand the specific specifications that align with your business model.

1. One-Pass Extraction Technology

The primary factor contributing to the ease of use is one-pass extraction. Unlike traditional crushers that require operators to feed the cane through multiple times to extract all the liquid, modern commercial units utilize a multi-roller system (typically 3 or 4 rollers) designed to extract up to 95% of the juice in a single feed.

- High Torque Gearboxes: These machines employ heavy-duty gear reduction systems. This allows the rollers to crush thick sugarcane stalks effortlessly without stalling, reducing the need for operators to precut or split the cane.

- Automatic Feeding: The operator simply inserts the cane into the feed inlet. The rollers grip the stalk and pull it through automatically, removing the need for physical pushing or force.

2. Built-in Safety Protocols

In an industrial setting, ease of use is synonymous with safety. If a machine is dangerous, operators will hesitate, slowing down production. Commercial sugarcane juicers incorporate several safety layers to ensure smooth operation:

- Enclosed Roller Design: Unlike open-wheel crushers, modern commercial units house the crushing mechanism inside a sealed cabinet. This prevents accidental contact with moving parts.

- Emergency Stop & Reverse Functions: Jams can happen, especially with irregular cane sizes. A dedicated reverse switch allows operators to instantly unclog the machine without disassembly, a feature that significantly reduces downtime.

- Overload Protection: Motors are often equipped with thermal overload sensors that automatically shut down the machine if it overheats, protecting the asset and the user.

3. Hygiene and Maintenance Simplicity

For food and beverage equipment, “easy to use” must extend to “easy to clean.” Bacterial growth is a major concern with sugary fluids. Commercial designs address this through modular construction.

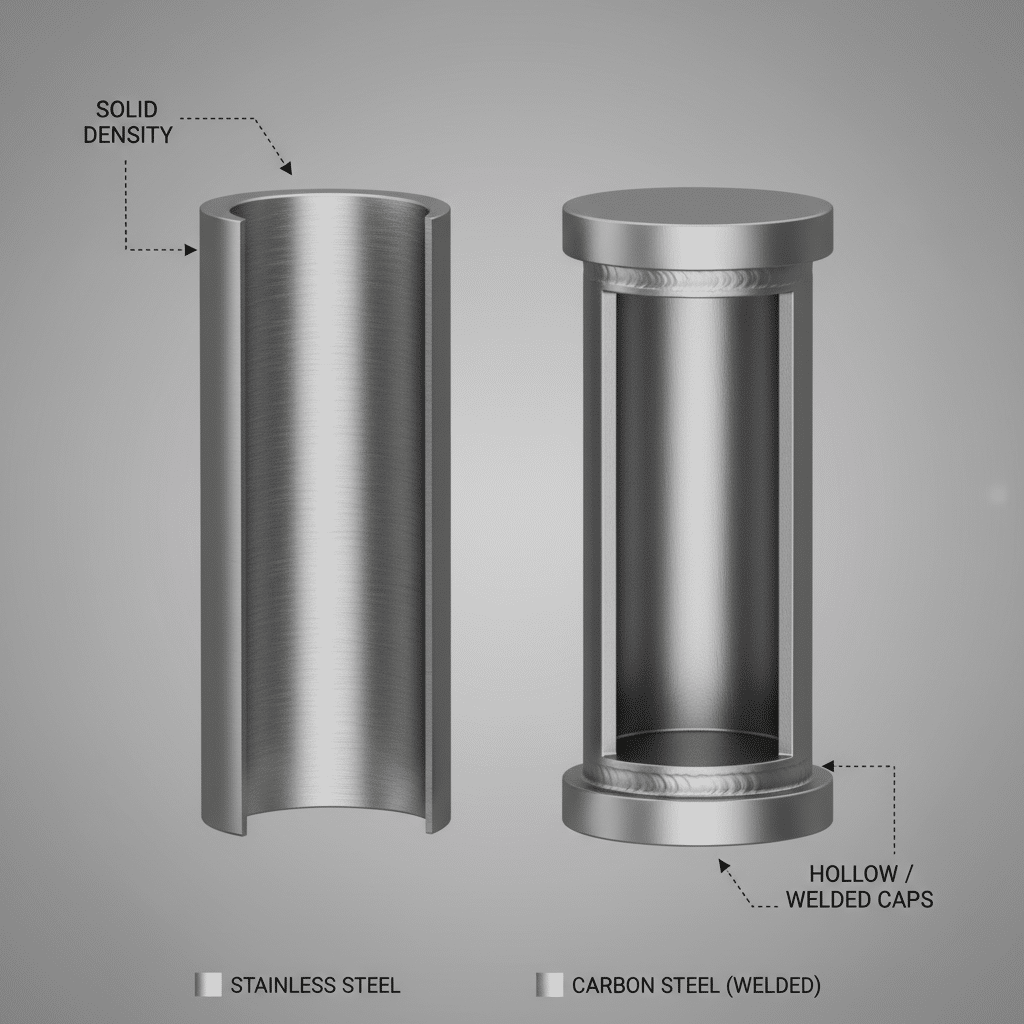

Food-Grade Materials

Top-tier machines are constructed from 304 stainless steel. This material is resistant to corrosion from acidic cane juice and is easy to wipe down. It does not harbor rust or contaminants, ensuring compliance with international food safety standards.

Detachable Components

Many models feature removable juice trays, filters, and tap assemblies. This allows staff to detach the parts that come into direct contact with the juice and wash them separately at the end of a shift. Efficient cleaning protocols are essential for maintaining equipment longevity and product quality.

4. Comparison: Commercial Electric vs. Manual Juicers

To highlight the operational advantages, the following table compares typical commercial electric models against manual alternatives.

| Feature | Commercial Electric Juicer | Manual / Traditional Juicer |

|---|---|---|

| Extraction Efficiency | High (One-pass, >90% yield) | Moderate (Requires multiple passes) |

| Operator Effort | Minimal (Auto-feed) | High (Manual cranking/pushing) |

| Safety | Enclosed, Emergency Stop | Exposed gears often pose risks |

| Throughput | 300–600 kg/hour (typical range) | 50–100 kg/hour |

| Cleaning | Detachable stainless parts | Often difficult to disassemble |

5. Operational Scenarios and Applications

Understanding where these machines excel helps in procurement planning. The “plug-and-play” nature of commercial sugarcane juicers makes them suitable for various high-demand environments:

- Supermarkets & Malls: The low noise operation of electric gear-driven models allows for fresh juice stations directly on the retail floor without disturbing customers.

- Beverage Processing Plants: For larger scale bottling, the consistency of extraction ensures standardized taste and yield, which is vital for brand reputation.

- Hotels & Resorts: Aesthetic stainless steel designs fit well in buffet setups, where staff can produce fresh juice on demand with minimal training.

6. Buying Guide: What Simplifies the Workflow?

When selecting a supplier or specific model, look for features that directly impact daily usability. Key specifications to verify include:

- Power Supply Compatibility: Ensure the motor voltage matches your local grid or facility standards to avoid the need for external transformers.

- Integrated Filtration: Some advanced models come with built-in mesh filters that strain the juice as it exits the rollers, removing fiber instantly and saving a processing step.

- Mobility: Heavy commercial units should be mounted on lockable caster wheels, making it easy to move the unit for floor cleaning or reconfiguration.

For answers to common technical questions regarding shipping, spare parts, and warranty terms, please visit our FAQs page.

Conclusion

Commercial sugarcane juicers are easy to use because they automate the most difficult parts of the process: the crushing force and the filtration. By combining high-torque motors with food-grade stainless steel engineering, these machines turn a physically demanding task into a streamlined, push-button operation. For businesses, this translates to lower labor costs, higher safety standards, and a consistent product.

Ready to upgrade your production line? Contact Easimaker today to request a quote or discuss custom specifications for your market.