In the competitive landscape of commercial juice bars and beverage manufacturing, the difference between a commodity product and a premium health beverage often lies in processing terminology and consumer perception. While sugarcane juice has traditionally been viewed as a low-cost street beverage in many regions, the global shift toward functional, raw, and nutrient-dense drinks presents a significant opportunity for operators.

By accurately leveraging the “cold-pressed” classification—which is inherent to the mechanical operation of professional sugarcane crushers—businesses can reposition this product. This shift allows for significantly higher price points, improved profit margins, and access to a health-conscious demographic willing to pay for quality preservation.

This guide explores the technical basis for labeling sugarcane juice as cold-pressed, the operational advantages of modern crushing equipment, and strategies for marketing this high-margin product effectively.

The Engineering Behind the “Cold-Pressed” Claim

To market a product as cold-pressed, the extraction method must minimize heat generation and oxidation. In the broader juice industry, this usually distinguishes hydraulic presses from centrifugal juicers (which use high-speed blades that introduce heat and air).

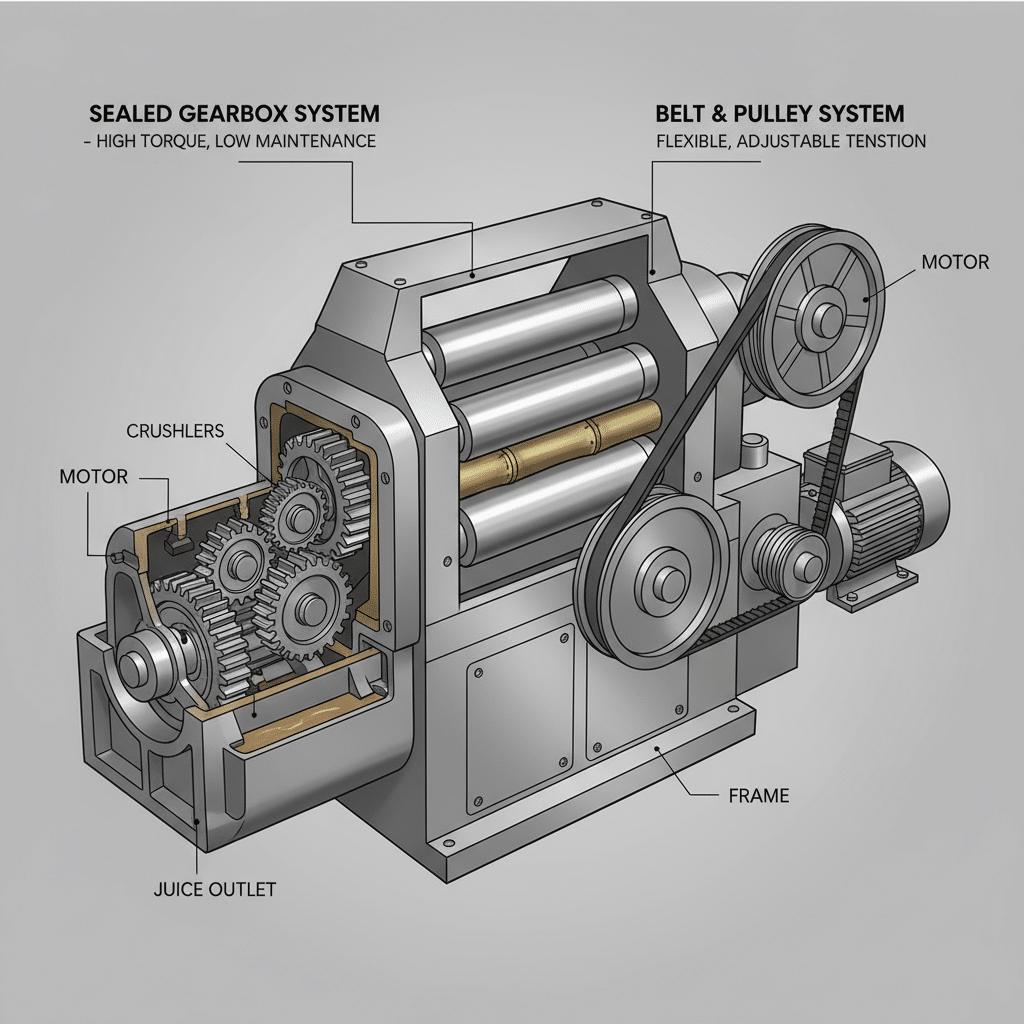

Professional sugarcane machines, specifically those utilizing multi-roller systems, naturally align with cold-pressed standards due to their mechanical design:

- Low RPM, High Torque: Unlike centrifugal juicers that spin at 3,000+ RPM, industrial sugarcane rollers typically rotate at low speeds (often 10–20 RPM). This slow rotation prevents the friction-based heat buildup that destroys heat-sensitive enzymes and vitamins.

- Masticating Action: The rollers utilize high pressure to crush and squeeze the fiber, extracting liquid without shredding the cane into a pulp that is exposed to rapid oxidation.

- No External Heat: The extraction is purely mechanical. As long as the machine is maintained and lubricated correctly (ensuring no gear heat transfers to the juice path), the juice remains at ambient temperature throughout the process.

For juice bar operators, this means the standard operating procedure of a high-quality sugarcane juicer technically qualifies the output as “cold-pressed,” a label that commands a premium in the current market.

Comparing Extraction Methods: Why It Matters for Pricing

Understanding the difference between extraction methods is crucial for justifying price increases to procurement teams or retail consumers.

| Feature | Centrifugal Extraction | Cold-Pressed / Roller Extraction |

|---|---|---|

| Mechanism | High-speed spinning blades | Slow-rotating steel rollers |

| Heat Generation | Moderate to High (Friction) | Negligible / None |

| Oxidation Rate | High (Aerates the juice) | Low (Preserves color longer) |

| Nutrient Retention | Lower (Enzyme degradation) | Maximum retention |

| Market Value | Standard / Economy | Premium / Luxury |

Operational Considerations for Premium Positioning

Simply owning a machine is not enough to secure a premium position. The equipment quality and operational workflow must support the high-value claim.

1. Material Compliance and Hygiene

To sell a premium health product, the equipment must meet stringent hygiene standards. Buyers should look for machines constructed with food-grade 304 stainless steel for all juice-contact parts (rollers, trays, filters). Older models using cast iron or non-food-grade alloys can introduce metallic tastes or rust contaminants, immediately invalidating any “pure” or “premium” marketing claims.

2. One-Pass Efficiency

High-end commercial machines are designed for “one-pass” extraction. This means the cane is crushed thoroughly in a single feed, extracting 95%+ of the juice. Cheaper machines often require feeding the cane through multiple times to get a decent yield. Multiple passes increase oxidation and handling time, degrading the “fresh” quality. Investing in a powerful, high-torque motor ensures single-pass efficiency, supporting a true cold-pressed workflow.

3. Filtration and Clarity

Cold-pressed consumers expect a smooth texture. Professional machines often include integrated fine-mesh filtration systems. Ensuring the final product is free of coarse fiber (bagasse) is essential for bottling and premium service.

Marketing Strategy: From Commodity to Superfood

Once the technical foundation is established, the marketing strategy must align with the premium price point. Sugarcane juice is naturally rich in electrolytes, antioxidants, and has a low glycemic index compared to refined sugars. The “cold-pressed” label acts as a trust signal that these properties have not been altered by processing.

Packaging and Presentation

Do not serve premium cold-pressed sugarcane juice in generic plastic cups. To command a higher price:

- Bottling: Use glass or high-quality rPET bottles with minimalist labeling. This implies shelf-stability (even if short-term) and quality.

- Visual Proof: If operating a juice bar, ensure the machine is visible. The visual of the slow-crushing stainless steel rollers reinforces the “fresh” and “mechanical” nature of the process, distinct from noisy blenders.

- Menu Terminology: Use terms like “Slow-Crushed,” “Raw Pressed,” and “Unpasteurized” alongside “Cold-Pressed.”

Strategic Blends

Pure sugarcane juice can be intensely sweet. To appeal to the health-conscious market and increase perceived value, create functional blends. The cold-press extraction method works excellently when co-extracting ingredients:

- The Detox Blend: Sugarcane + Ginger + Lemon (Ginger can often be crushed directly in robust rollers).

- The Immunity Blend: Sugarcane + Turmeric + Calamansi.

Buying Guide: Selecting the Right Machine

When sourcing equipment to support a premium sugarcane juice business, consider the following specifications to ensure reliability and product quality:

- Roller Composition: Solid stainless steel rollers are preferred over hollow or coated rollers for durability and hygiene.

- Safety Features: Look for emergency stop buttons and enclosed feed chutes. In many jurisdictions, open-roller machines are prohibited in commercial settings due to injury risks.

- Cleaning Accessibility: Cold-pressed juice is highly perishable. The machine must be easy to disassemble for deep cleaning to prevent bacterial growth. Removable rollers and juice trays are a critical feature.

- Noise Level: Premium juice bars often value ambiance. A high-quality gear reduction motor should operate quietly, unlike the high-pitched whine of centrifugal juicers.

Frequently Asked Questions (FAQs)

Does “cold-pressed” sugarcane juice have a longer shelf life?

Cold-pressed juice generally has a slightly longer shelf life than centrifugal juice due to reduced oxidation, but raw sugarcane juice is highly perishable. Without pasteurization or preservatives, it typically lasts 24–48 hours under refrigeration. The premium value comes from its freshness, not long-term storage.

Can I bottle sugarcane juice for retail sale?

Yes, but strict cold-chain management is required. Because the juice is raw and rich in natural sugars, fermentation can start quickly. Bottling immediately after extraction and keeping the product below 4°C (39°F) is essential. Consult local health regulations regarding raw juice sales.

What is the typical yield of a professional sugarcane crusher?

A high-efficiency 3-roller or 4-roller machine can typically extract 70% to 80% of the cane’s weight as juice in a single pass. This high yield is critical for maintaining healthy profit margins.

Why does sugarcane juice turn brown, and does cold-pressing stop it?

Browning is caused by the oxidation of enzymes and polyphenols in the juice. While cold-pressing significantly slows this process compared to centrifugal juicing, it does not stop it entirely. Adding a small amount of acidic citrus (lemon or lime) during extraction helps maintain the bright green color.

Is a 3-roller or 4-roller machine better for premium juice?

Generally, more rollers allow for more gradual pressure steps, maximizing yield and ensuring the fiber is completely dry upon exit. A 3-roller system is the industry standard for balancing efficiency and cost, while 4-roller systems are used for high-volume industrial applications.

Ready to upgrade your beverage menu with high-margin, cold-pressed sugarcane juice?