In the beverage industry, few products offer the profit margins of fresh sugarcane juice. With raw material costs often negligible compared to the retail price of a cup, it is a lucrative addition to juice bars, restaurants, and hotels. However, the profitability of this venture relies heavily on one piece of equipment: the commercial sugar cane juicer.

Selecting the right machine is not just about crushing cane; it is about extraction efficiency (yield), hygiene, and operational reliability. If your machine leaves juice in the fiber (bagasse), you are throwing money away. If it breaks down during a rush or is difficult to clean, it becomes a liability rather than an asset.

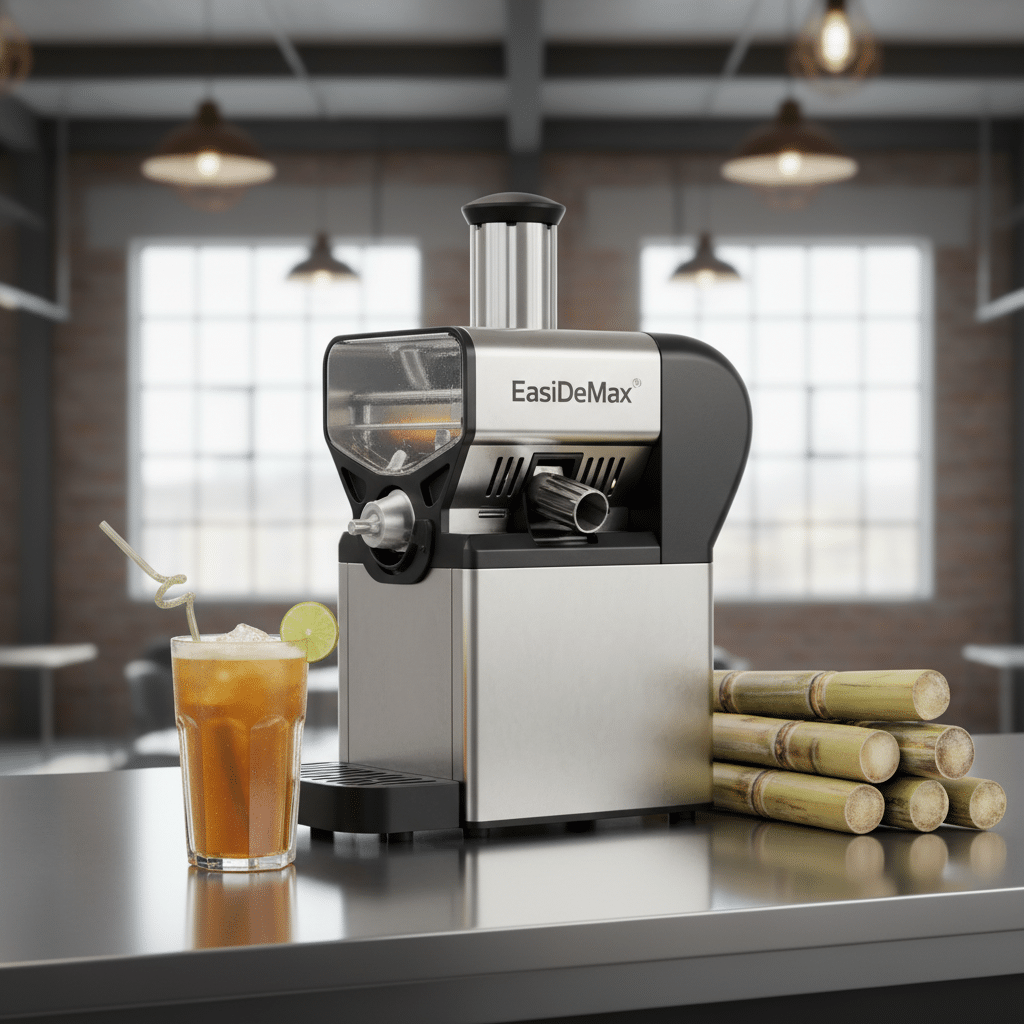

Enter the EasiDeMax S4. Designed specifically for high-demand commercial environments, the S4 addresses the most common pain points faced by business owners: low yield, noise, and sanitation concerns. In this guide, we explore the five engineering and operational reasons why the EasiDeMax S4 is the strategic choice for your business.

1. Maximum Extraction: The Power of the 4-Roller System

The primary metric for any commercial juicer is yield: how much juice can you extract from a specific weight of cane? Standard machines often utilize a 2-roller or 3-roller system. While these can crush cane, they often require multiple passes to extract all the liquid, or they simply discard wet bagasse, resulting in significant product loss.

The EasiDeMax S4 utilizes a 4-roller system designed to maximize throughput and extraction in a single pass.

How the 4-Roller System Works

The mechanics are progressive. The first set of rollers acts as the initial crusher, breaking the hard outer bark of the sugarcane and flattening the stalk. The second set applies immense pressure to squeeze the fiber dry. This multi-stage compression ensures a juicing yield of up to 75%.

Business Impact:

- Higher Margins: A 75% yield means you get more product from the same inventory compared to machines offering only 60-65% yield. Over a year, this difference equates to substantial savings in raw material costs.

- Speed: Because the extraction is efficient in a single pass, operators do not need to feed the cane through multiple times, speeding up service during peak hours.

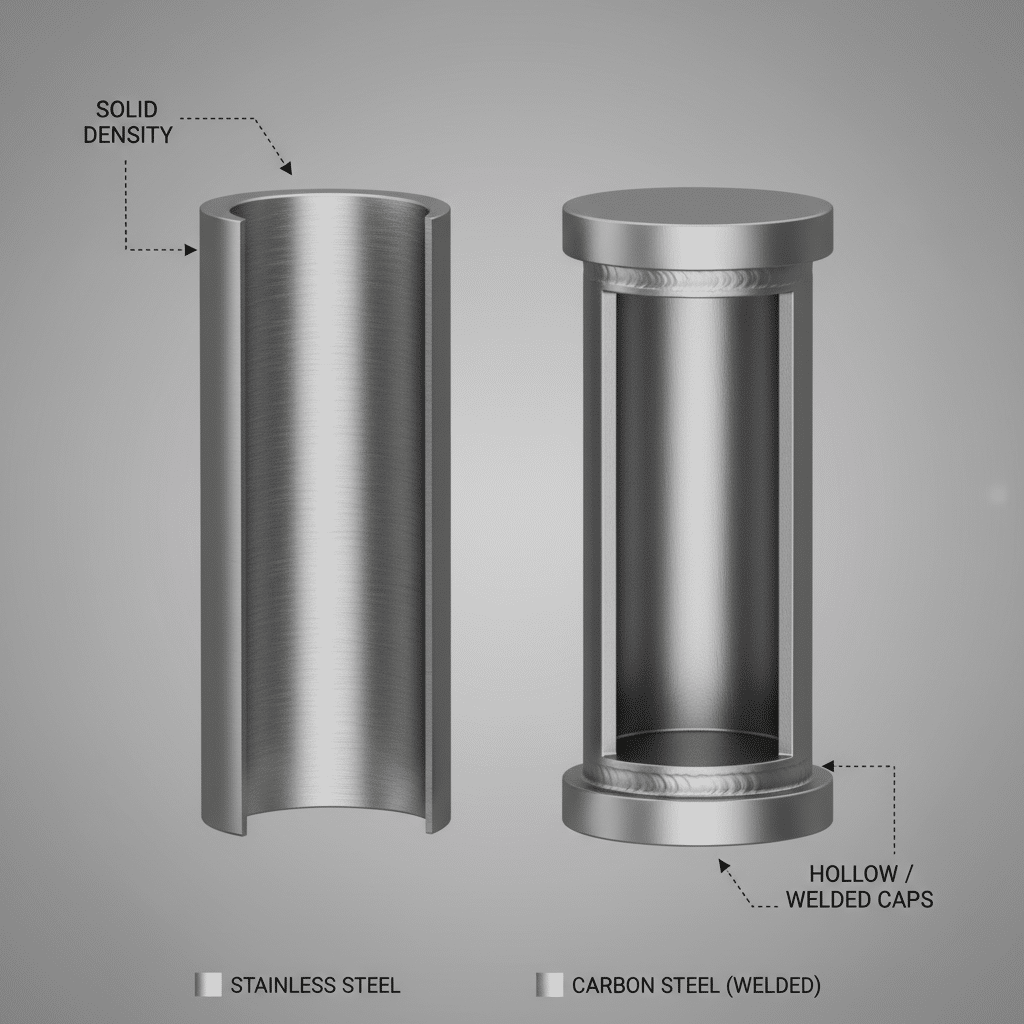

2. Food Safety & Durability: 304 Stainless Steel Construction

In the food processing industry, material quality is non-negotiable. Cheaper alternatives often use 201 stainless steel or even galvanized iron for internal components. These materials are prone to rust and corrosion when exposed to the acidic nature of sugarcane juice, posing serious health risks and leading to equipment failure.

The EasiDeMax S4 is constructed with food-grade 304 stainless steel. This applies to the cabinet and, crucially, the rollers and juice contact areas.

Why 304 Stainless Steel Matters

- Corrosion Resistance: 304 stainless steel contains a high percentage of chromium and nickel, making it highly resistant to oxidation and rust. This ensures the machine remains hygienic and visually appealing for years.

- Compliance: Using food-grade materials helps your business meet strict local health department regulations and international food safety standards.

- Aesthetics: The polished finish looks professional in front-of-house settings, reassuring customers about the cleanliness of your operation.

For more insights on material importance, read our guide on how to choose a commercial sugar cane juice machine.

3. Reliability: Heavy-Duty Copper Motor & Overload Protection

A commercial machine must withstand continuous operation. The heart of the EasiDeMax S4 is its built-in all-copper motor, rated at a minimum of 1/2 HP (Horsepower). Unlike aluminum-wound motors found in budget units, copper motors conduct electricity more efficiently, generate less heat, and offer a significantly longer lifespan.

Engineered for Longevity

The S4 is not just powerful; it is smart. It features an integrated overload protection system. If an operator accidentally feeds an oversized stalk or a hard object that jams the rollers, the system automatically cuts power to prevent motor burnout. This safety feature protects your investment and minimizes downtime.

Super Low Noise Operation

Many industrial juicers sound like tractors, making them unsuitable for juice bars, cafes, or hotel lobbies where ambiance is key. The EasiDeMax S4 is engineered for super low noise. The precision gear reduction box and high-quality motor ensure quiet operation, allowing your staff to communicate with customers without shouting over the machine.

4. Hygiene & Maintenance: The Removable Roller Advantage

Cleaning is often the most dreaded task for juice bar operators. In many traditional machines, the rollers are fixed inside the cabinet. To clean them, staff must reach into the machine with a hose or brush, often missing crevices where sugar residue can ferment and grow bacteria.

The EasiDeMax S4 solves this with a removable roller design. The roller assembly can be easily detached and removed from the cabinet. This allows for:

- Deep Cleaning: You can wash the rollers thoroughly in a sink, ensuring 100% removal of sticky residue.

- Sanitation: Prevents cross-contamination and the buildup of mold or yeast.

- Maintenance Access: Makes it easier to inspect bearings and seals without dismantling the entire unit.

5. Operational Efficiency: Designed for the Front-of-House

The EasiDeMax S4 is designed not just for the kitchen, but for the customer experience. The machine features a transparent window on the front. This serves a dual purpose:

- Operational Safety: The operator can visually monitor the crushing process.

- Marketing Theater: Customers love to see their juice being made fresh. Seeing the cane crushed and the juice flowing creates an authentic, fresh appeal that drives sales.

Furthermore, the control system is simplified into a two-button control (Forward/Reverse). This simplicity reduces the training time required for new staff. If a piece of cane is tricky, the reverse function allows the operator to back it out instantly.

Comparison: EasiDeMax S4 (4-Roller) vs. Standard 2-Roller Machines

To understand the value proposition of the S4, it is helpful to compare it directly with entry-level 2-roller machines often found in the market.

| Feature | Standard 2-Roller Machine | EasiDeMax S4 (4-Roller) |

|---|---|---|

| Juicing Yield | 60% – 65% (Wet bagasse) | Up to 75% (Dry bagasse) |

| Passes Required | Often requires 2-3 passes | Single pass efficiency |

| Motor Type | Often Aluminum or low torque | All-Copper, High Torque (1/2 HP+) |

| Hygiene | Fixed rollers (Hard to clean) | Removable rollers (Easy clean) |

| Noise Level | Loud, mechanical noise | Super low noise operation |

| Durability | Plastic or 201 Stainless components | Full 304 Stainless Steel |

Buyer’s Checklist: What to Ask Before You Buy

Before finalizing your procurement of a sugarcane juicer, ensure you have checked the following specifications to guarantee compatibility with your business needs.

- Voltage & Plug Type: Ensure the machine matches your local power grid (e.g., 110V/60Hz for US, 220V/50Hz for EU/Asia).

- Spare Parts Availability: Does the supplier stock gears, chains, and bearings?

- Warranty Terms: Understand what is covered. Check the warranty policy to ensure the motor and gearbox are protected.

- Capacity Requirements: Estimate your peak hour demand. The S4 is designed for high volume, but ensure your workflow can handle the output.

Frequently Asked Questions (FAQ)

Does the EasiDeMax S4 require peeling the sugarcane before juicing?

While the heavy-duty rollers can crush unpeeled cane, it is generally recommended to lightly peel or clean the cane for the best taste and hygiene. Hard outer skins can sometimes impart a bitter taste, but the machine has the power to process them if required.

How often should the machine be cleaned?

Due to the high sugar content of the juice, the machine must be cleaned every few hours during operation (flushing with water) and deep cleaned at the end of every shift. The removable rollers on the S4 make this end-of-day process significantly faster.

Can this machine handle different sizes of sugarcane?

Yes, the roller gap is designed to accommodate various diameters of sugarcane stalks, from thin to thick varieties. The automatic adjustment mechanism ensures consistent pressure regardless of stalk size.

Is the machine suitable for mobile juice carts?

Yes, provided there is a stable power source. Its compact footprint, low noise, and enclosed hygienic design make it ideal for mobile setups, food trucks, and kiosks.

Conclusion

The EasiDeMax S4 represents a balance of heavy-duty industrial capability and user-friendly design. By combining a high-yield 4-roller system with 304 stainless steel hygiene and a quiet, powerful copper motor, it eliminates the inefficiencies of older juicing methods.

For businesses looking to scale their operations and ensure a consistent, high-quality product, the S4 is a verified investment. Don’t let profits disappear with wet bagasse or downtime.

Ready to upgrade your production?