For commercial juice bars and beverage manufacturers, sugarcane juice offers an excellent base product due to its high yield and natural sweetness. However, relying solely on pure sugarcane juice can limit market reach and profit potential. By introducing strategic blends—mixing sugarcane with ingredients like ginger, lemon, kumquat, or mint—businesses can create premium menu items that command higher price points.

Expanding a menu requires more than just creativity; it requires technical compatibility. Not all sugarcane juicers can handle fibrous rhizomes or acidic citrus fruits without jamming or suffering from component corrosion. This guide explores profitable recipe concepts and the operational requirements for co-pressing ingredients efficiently.

The Economics of Blends: Why Diversify?

From a B2B perspective, the primary motivation for blending is margin expansion and differentiation. Pure sugarcane juice is often viewed as a commodity. A signature blend transforms that commodity into a value-added product.

- Increased Ticket Value: Adding low-cost ingredients like a few grams of ginger or a splash of lemon can justify a price increase of 20–30% compared to the base product.

- Flavor Balancing: Raw sugarcane has a high Brix level (sugar content). Acidic or spicy additions cut through the sweetness, making the beverage palatable to a wider demographic that might find pure juice too sweet.

- Health Positioning: Ingredients like ginger and turmeric allow brands to market drinks as functional beverages or immunity boosters, tapping into the wellness trend.

Top Commercial Sugarcane Juice Recipes

When designing a menu for a commercial setting, consistency and speed are key. The following blends are industry standards globally because they are operationally simple and widely accepted.

1. The Classic Citrus Balance (Sugarcane + Lemon/Lime/Kumquat)

This is the most common variation worldwide. The acidity of the citrus prevents the sugarcane juice from oxidizing (turning brown) too quickly while balancing the glucose profile.

- Ratio: Typically 1 part citrus juice to 10–15 parts sugarcane juice.

- Method: Co-pressing small wedges of citrus with the cane stalks creates a more integrated flavor than stirring in juice afterward, as the roller pressure extracts essential oils from the rind (if using kumquats or specific lime varieties).

2. The Digestive Kick (Sugarcane + Ginger)

Popular in Asian markets, this blend adds a spicy note that complements the cooling nature of the cane.

- Ratio: Approx. 10g of fresh ginger root per 250ml of juice.

- Method: Ginger is highly fibrous. It is best fed into the machine alongside a cane stalk to ensure the rollers grip it effectively and push it through the extraction zone.

3. The Refreshing Herbal (Sugarcane + Mint/Basil)

Herbs add aroma without significantly altering the sugar profile.

- Method: Herbs are delicate. To extract flavor without pulverizing the leaves into unappealing sediment, they should be sandwiched between two split cane stalks before feeding into the machine.

Technical Challenges: Co-Pressing vs. Mixing

There are two ways to create these blends: mixing separate liquids post-extraction or co-pressing ingredients simultaneously. For high-volume operations, co-pressing is often preferred for speed and flavor integration, but it presents mechanical challenges.

Handling Fibrous Ingredients (Ginger)

Ginger root is dense and fibrous. Standard light-duty juicers often struggle to crush ginger, leading to jams or motor stalls. If the rollers lack sufficient torque or surface grip (knurling), the ginger may slip or clog the discharge chute.

Solution: Use heavy-duty commercial juicers with high-torque gearboxes and stainless steel rollers designed with aggressive knurling. The machine must have the power to crush the dense fiber without hesitating.

Managing Acidity (Lemon/Pineapple)

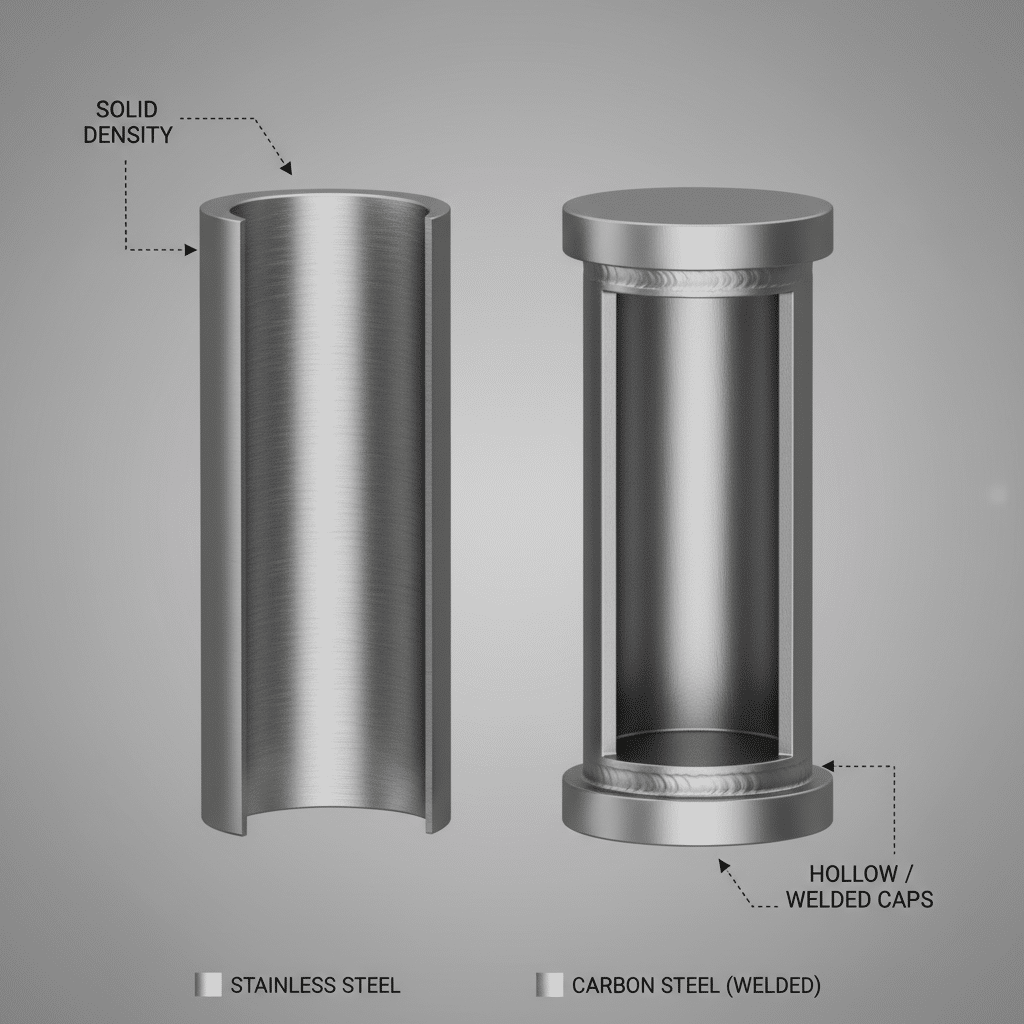

Citrus fruits are highly acidic. If a machine utilizes cast iron or non-food-grade aluminum rollers, the acid will react with the metal, potentially causing rust or leaching metallic tastes into the product.

Solution: Ensure your equipment features 304-grade stainless steel rollers and juice trays. Stainless steel is non-reactive and essential for maintaining food safety standards when processing acidic blends.

Operational Workflow for Blended Juices

To maintain efficiency and prevent equipment downtime when serving blends, follow these operational best practices:

1. Ingredient Preparation

Do not feed whole large lemons or massive ginger roots into the machine. This increases wear on the bearings and motor.

- Ginger: Slice into long, flat strips or smaller chunks that can easily ride the friction of the rollers.

- Citrus: Cut into wedges. Remove seeds if possible, as crushed seeds can introduce bitterness.

2. Feeding Sequence

To prevent clogging, never feed fibrous additives alone. Always pair them with a sugarcane stalk. The stalk acts as a carrier, pushing the smaller, fibrous ingredients through the rollers and out the bagasse chute.

3. Cleaning Protocols

Sugarcane juice is high in sugar, and additives like lemon are acidic. This combination can create a sticky, corrosive residue. Machines used for blends must be flushed with water immediately after a shift. Removable rollers and juice compartments are critical features for thorough sanitation.

Choosing the Right Machine for a Versatile Menu

Not all extractors are built for menu diversity. When sourcing equipment intended for blends, evaluate the following specifications:

| Feature | Requirement for Blends | Why it Matters |

|---|---|---|

| Roller Material | 304 Stainless Steel | Resists corrosion from acidic fruits like lemon and pineapple. |

| Motor Power | High Torque / Heavy Duty | Prevents stalling when crushing dense ginger roots. |

| Reverse Function | Mandatory | Allows the operator to clear jams quickly if an ingredient gets stuck. |

| Filtration | External / Easy Clean | Blends create different pulp textures; filters must be easy to rinse. |

Frequently Asked Questions

Can I juice whole lemons with the peel in a sugarcane machine?

Technically, many industrial machines can crush a lemon wedge with the peel. However, the peel contains bitter oils. For a smoother taste, many operators peel the lemon or use limes/kumquats which have thinner, less bitter skins. Always test small batches first.

Will adding ginger damage the rollers?

Ginger will not damage stainless steel rollers, but it can strain the motor of an underpowered machine. Ensure your unit is rated for commercial use. If the machine struggles, cut the ginger into smaller pieces.

How do I prevent flavor cross-contamination?

If you serve pure cane juice and spicy ginger blends from the same machine, there is a risk of flavor transfer. The most effective method is to run a “flush” using a plain sugarcane stalk or a small amount of water between different recipes, or to batch produce the blends at specific times.

What is the shelf life of sugarcane blends?

Fresh sugarcane juice oxidizes rapidly. Adding acidic ingredients like lemon or lime actually helps lower the pH and can slightly delay oxidation, keeping the juice green for longer. However, for a fresh product without preservatives, it should still be consumed immediately or refrigerated for no more than 24 hours.

Conclusion

Expanding your menu with sugarcane juice blends is a low-risk, high-reward strategy for increasing revenue. By understanding the technical capabilities of your machinery and adhering to proper preparation methods, you can offer a diverse range of high-quality beverages without compromising operational efficiency.

Ready to upgrade your equipment for a versatile menu?