Maximizing Revenue Per Square Foot in Small Cafes

For urban cafes and coffee shops, floor space is a premium asset. Every square foot of counter space must generate revenue. While specialty coffee remains the anchor, diversifying into fresh, high-margin beverages like sugarcane juice can significantly increase average ticket size. However, the challenge lies in integration: traditional sugarcane crushers are often bulky, noisy, and industrial-looking, making them unsuitable for a refined cafe atmosphere.

Modern compact sugarcane juicers address this friction. By selecting equipment designed specifically for limited footprints, cafe owners can introduce a lucrative fresh juice menu without compromising the barista’s workflow or the customer experience. This guide explores how to select, position, and operate compact units to maximize efficiency.

The Business Case: Why Sugarcane in a Cafe?

Before altering a layout, it is essential to evaluate the operational value. Sugarcane juice offers distinct advantages over bottled beverages or complex smoothie stations:

- High Margins: Raw sugarcane is inexpensive compared to the final retail price of fresh juice. The cost-to-profit ratio is typically more favorable than milk-based espresso drinks.

- Speed of Service: A high-performance compact machine can extract a glass of juice in 10–15 seconds, comparable to pulling an espresso shot.

- Visual Appeal: The extraction process is mechanical and visual, adding “theater” to the customer experience, similar to watching a barista work.

Workflow ergonomics: The “Zone” Approach

Introducing a juicer should not disrupt the primary coffee workflow. The goal is to create a parallel workstation that allows for simultaneous service without cross-traffic collisions.

1. The Barista Zone (Do Not Disturb)

The area immediately surrounding the espresso machine and grinder is sacred. Adding a juicer here creates bottlenecks. Baristas need unobstructed access to the knock box, milk pitchers, and serving pass.

2. The Cold Beverage Station (Ideal Placement)

Compact sugarcane machines are best situated in a dedicated “wet” zone, distinct from the espresso setup. This station should handle cold drinks, iced teas, and juices. This separation ensures that a second staff member can operate the juicer during peak hours without elbowing the barista.

3. Front-of-House vs. Back-of-House

Because modern compact machines are often designed with aesthetics in mind (stainless steel finishes, enclosed rollers), they are suitable for front-of-house placement. Placing the machine on the front counter signals freshness to the customer. However, if counter depth is less than 60cm (24 inches), a back-bar placement may be safer to prevent accidental bumps.

Selecting the Right Compact Machine

Not all “small” machines are built for commercial cafe environments. When sourcing a compact sugarcane juicer, prioritize the following specifications:

Footprint and Dimensions

A true compact commercial unit should typically fit within a footprint of approximately 40cm x 50cm (16” x 20”). Vertical design is preferable to horizontal design, as it consumes less counter width. Ensure the machine fits under overhead cabinets if applicable; standard clearance is usually 45–50cm.

Noise Levels (Decibels)

Ambiance is critical in a cafe. Industrial crushers often exceed 80dB, which disrupts conversation and music. Look for machines with high-quality gearboxes and motor insulation, rated below 70dB. This allows the machine to operate front-of-house without startling customers.

Safety Features

In a fast-paced environment, safety is non-negotiable. The machine must have:

- Fully Enclosed Rollers: To prevent finger injuries.

- Emergency Stop Button: Easily accessible on the front panel.

- Overload Protection: To prevent motor burnout if a particularly hard stalk is inserted.

Hygiene and Cleaning Efficiency

Sugarcane juice is high in sugar and ferments quickly. The machine must be easy to clean to maintain health standards and workflow speed.

Key feature to look for: Removable rollers and juice compartments. If a staff member has to spend 20 minutes unscrewing parts to clean the machine, it is not suitable for a busy cafe. Ideally, daily cleaning should take less than 10 minutes.

Technical Specifications & Installation

Ensure your facility can support the equipment before purchasing.

| Feature | Requirement for Cafe Use |

|---|---|

| Power Supply | Standard 110V/220V (Check local standard). Avoid 3-phase requirements for countertop units. |

| Motor Power | Minimum 0.5 HP to handle continuous crushing without stalling. |

| Material | Food-grade 304 Stainless Steel (corrosion resistance is vital due to acidic juice). |

| Waste Disposal | Direct chute to under-counter bin is preferred to manage bagasse (waste fiber) cleanly. |

Managing Waste (Bagasse) in Small Spaces

One operational reality of sugarcane juicing is the volume of dry fiber waste (bagasse). In a limited space, this can accumulate quickly.

- Through-Counter Chutes: Some compact machines allow waste to drop directly through a hole in the counter into a hidden bin below. This is the cleanest solution for small spaces.

- Side-Ejection: If through-counter isn’t an option, ensure the machine ejects waste into a contained bin, not onto the counter surface.

- Disposal Strategy: Plan for frequent emptying of the bagasse bin. Bagasse is excellent for composting; partnering with a local community garden can be a sustainable marketing angle for the cafe.

Buying Guide: Sourcing for Reliability

When procuring a compact sugarcane juicer for a commercial setting, consider the following beyond just the price tag:

Warranty and Parts Availability

Commercial equipment endures heavy daily use. Ensure the supplier provides a warranty (typically 1 year for parts) and stocks essential spares like bearings, rollers, and capacitors. Downtime equals lost revenue.

Certifications

Depending on your region, health inspectors may require specific certifications (e.g., CE, NSF, or UL). Verify that the machine meets the electrical and sanitation standards required by your local jurisdiction.

Demonstration and Sampling

If possible, request a video demonstration or a trial. Observe the noise level and the speed of the roller mechanism. A slow machine will cause queues; a loud machine will ruin the atmosphere.

FAQ

How much space do I strictly need for a sugarcane station?

Beyond the machine’s footprint (approx. 40x50cm), allow at least 20cm on the feed side for maneuvering the cane stalks and 20cm on the waste side if using a tabletop bin. A 1-meter section of counter is usually sufficient for the entire station.

Can compact machines handle tough sugarcane varieties?

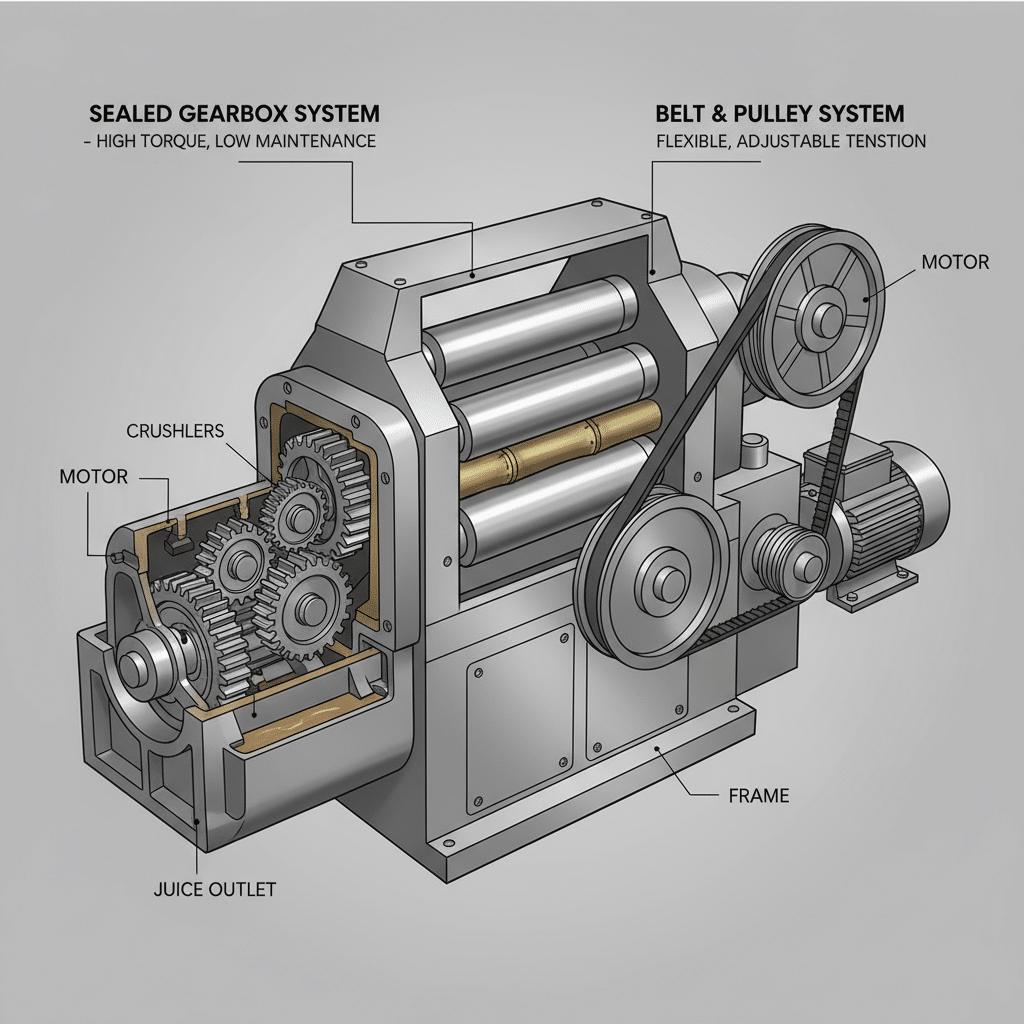

Yes, high-quality compact machines utilize high-torque gearboxes designed to crush standard sugarcane varieties. However, it is always recommended to split very thick stalks or cut them at an angle to ease the initial feed.

Does the machine require a water connection?

Most compact sugarcane juicers are standalone and do not require plumbing. They are cleaned manually. However, having a sink nearby is essential for rinsing pitchers and cleaning removable parts.

How often does the machine need maintenance?

Daily cleaning is mandatory. Lubrication of the chain or gears (if not sealed) is typically required monthly or quarterly, depending on usage volume. Check the manual for specific grease types (food-grade grease is usually required for exposed components).

Ready to Optimize Your Beverage Station?

Integrating a sugarcane juicer into your cafe can drive significant revenue without expanding your floor plan. By choosing the right compact equipment, you ensure a seamless workflow and a premium customer experience.

Request a quote / Get a sample to discuss which compact model best fits your specific counter layout and volume requirements.