In the beverage processing industry, commercial sugarcane juicers are distinct due to the sheer mechanical force required to operate them. Unlike citrus or centrifugal juicers, sugarcane extractors rely on high-torque rollers to crush fibrous stalks. While this efficiency is necessary for yield, it introduces specific mechanical hazards that business owners and procurement managers must address.

Prioritizing mechanical safety standards is not merely about regulatory compliance; it is a critical strategy for liability mitigation and workforce protection. For B2B buyers, understanding the physical safety mechanisms of these machines—from emergency stops to anti-crush protocols—is essential when selecting equipment for juice bars, hotels, or industrial processing facilities.

This guide details the key mechanical safety features you should look for to ensure your operations remain safe, efficient, and compliant.

The Mechanics of Risk: Understanding Nip Points

To evaluate safety, one must first understand the hazard. The primary danger zone in a sugarcane juicer is the “nip point”—the area where two rollers converge to pull the cane in. The torque required to crush a sugarcane stalk is sufficient to cause severe injury to a human hand in a fraction of a second.

Standard consumer-grade safety features are often insufficient for this level of force. Industrial-grade safety relies on preventing access to these nip points entirely and ensuring immediate cessation of movement if a breach occurs.

Critical Mechanical Safety Features

When sourcing commercial sugarcane juicers, the following physical protection features should be non-negotiable in your technical specifications.

1. Accessible Emergency Stop (E-Stop) Systems

A standard power switch is not an emergency safety device. An industrial E-stop button is a specific requirement for heavy machinery.

- Visibility and Access: The button should be prominent, typically red on a yellow background, and mushroom-shaped for easy activation. It must be positioned within immediate reach of the operator’s normal working stance.

- Latching Mechanism: Once pressed, the E-stop should lock in the “off” position, preventing the machine from restarting until the button is manually reset. This prevents accidental restart while an obstruction is being cleared.

- Braking Speed: In high-quality units, activating the E-stop should engage an electronic or mechanical brake to stop the rollers instantly, rather than letting them coast to a halt.

2. Feed Chute Geometry and Tunnel Guards

The most effective way to prevent injury is to physically prevent the operator from reaching the rollers. This is achieved through the design of the feed chute.

- Restricted Aperture: The feed opening should be sized to accommodate sugarcane stalks but too narrow for an adult hand to pass through.

- Tunnel Distance: The length of the feed chute (the distance from the opening to the rollers) is critical. International safety engineering principles often dictate that the distance must be greater than the reach of a finger or hand.

- Tamper-Proofing: Guards should be fixed in a way that requires tools to remove, discouraging operators from bypassing safety measures for “convenience.”

3. Safety Interlocks and Enclosures

Commercial environments require frequent cleaning, which involves opening the machine. Safety risks increase significantly during disassembly.

Micro-switch Interlocks: Modern commercial juicers should feature electrical interlocks on the casing. If the outer housing or cleaning hatch is opened, the circuit is physically broken, and the motor cannot run. This prevents the machine from being operated while internal gears or rollers are exposed.

4. Anti-Crush and Reverse Functionality

Jams are inevitable when processing natural products with varying thickness and density.

- Reverse Switch: A dedicated reverse function allows the operator to back a jammed stalk out of the machine mechanically. Without this, operators may be tempted to pull the stalk manually while the machine is straining forward, creating a high-risk scenario.

- Overload Protection: Thermal overload sensors should automatically cut power if the motor strains beyond a safe limit, protecting both the machine’s drivetrain and the operator.

Comparing Safety Configurations

Not all commercial juicers offer the same level of protection. Below is a comparison of standard versus advanced safety configurations.

| Feature | Standard / Entry-Level | Advanced / Safety-Compliant |

|---|---|---|

| Stop Mechanism | Simple On/Off Toggle | Latching E-Stop Mushroom Button |

| Feed Inlet | Open wide chute | Extended tunnel with restricted aperture |

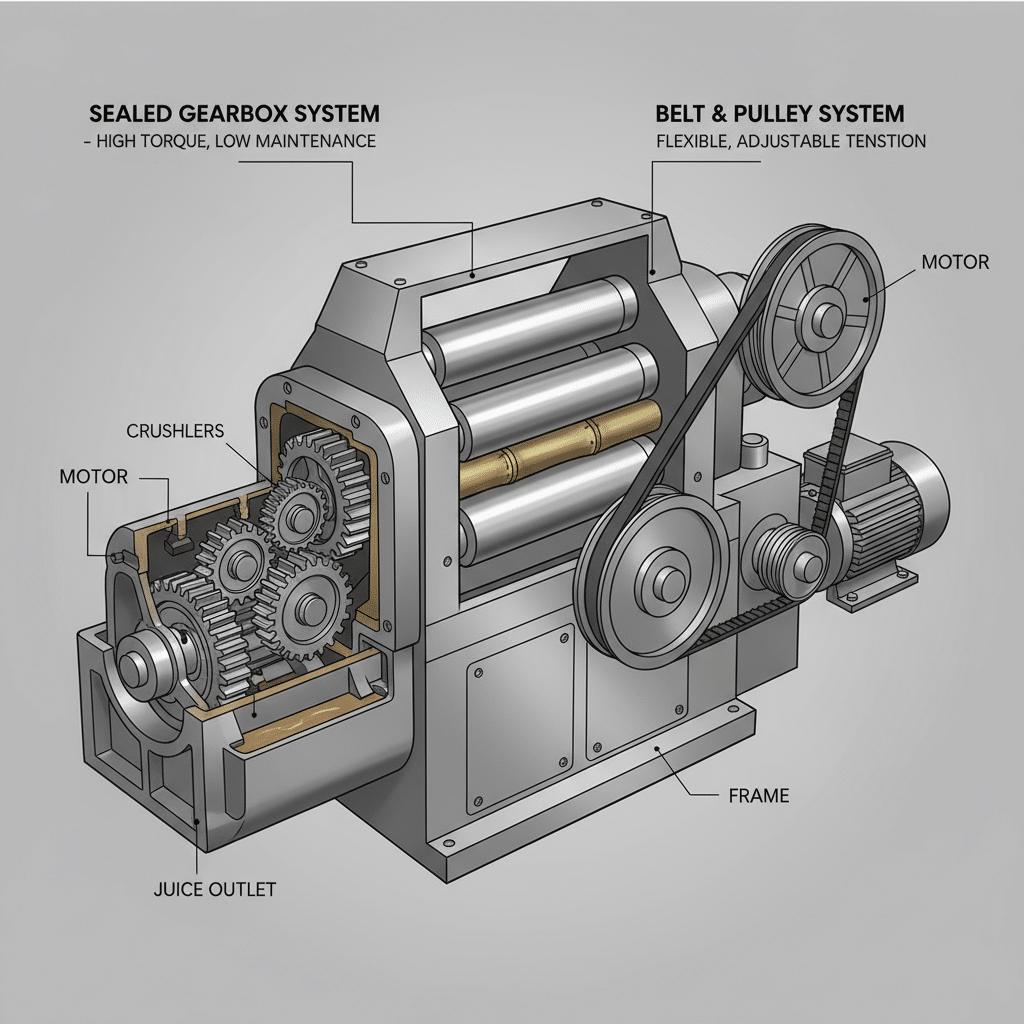

| Drive Components | Exposed belts/chains (sometimes) | Fully enclosed gearbox & motor |

| Jam Clearing | Manual force required | Instant Reverse Switch |

| Cleaning Safety | None (Operator caution relied upon) | Magnetic/Mechanical Interlocks |

Operational Safety Protocols

Even the safest machinery requires proper operational protocols. Investing in hardware is only half the equation; the workflow must also support safety.

Training and Authorization

Ensure that only trained personnel are authorized to operate the sugarcane juicer. Training should cover:

- Proper feeding techniques (never using hands to push cane).

- How to use the E-stop and Reverse functions.

- Lockout/Tagout procedures during deep cleaning or maintenance.

Daily Inspection Checklists

Before a shift begins, a brief visual inspection should be conducted:

- Guard Check: Are all feed chutes and covers securely attached?

- Function Test: Does the E-stop actually stop the machine immediately?

- Stability: Is the machine on a stable, non-slip surface to prevent movement during operation?

Buying Guide: Questions for Suppliers

When contacting manufacturers or distributors, asking the right technical questions can reveal the quality of the equipment.

- “Does the machine have active safety interlocks on the cleaning panels?” (If the answer is no, the risk of injury during maintenance is higher.)

- “What is the stopping time of the rollers once the E-stop is pressed?” (Instant is preferred.)

- “Are the rollers fully enclosed during operation?”

- “Can you provide a user manual detailing the safety diagrams?”

Frequently Asked Questions

Do commercial sugarcane juicers require special electrical setups?

Many heavy-duty commercial units run on standard voltage, but due to the high torque, they may require a dedicated circuit to prevent tripping breakers. Always check the amperage requirements.

Can I retrofit safety guards onto an older machine?

While some aftermarket guards exist, retrofitting is often discouraged as it may not integrate correctly with the machine’s original design or interlock systems. It is generally safer and more cost-effective to upgrade to a machine designed with modern safety standards.

How often should the safety features be tested?

Safety features like the E-stop and interlocks should be tested daily before operations begin. If a safety feature fails, the machine should be tagged out of service immediately.

Why is stainless steel preferred for safety?

Beyond hygiene, high-grade stainless steel (like 304) provides structural integrity. Plastic guards can crack under vibration or impact, creating sharp edges or exposing moving parts. Stainless steel ensures the guards remain intact over years of heavy use.

Secure Your Operations

Investing in equipment with robust mechanical safety standards protects your staff and safeguards your business reputation. Do not compromise on operator protection.

Ready to upgrade your equipment?

Request a quote / Get a sample