The Shift to Experiential Retail in the Produce Aisle

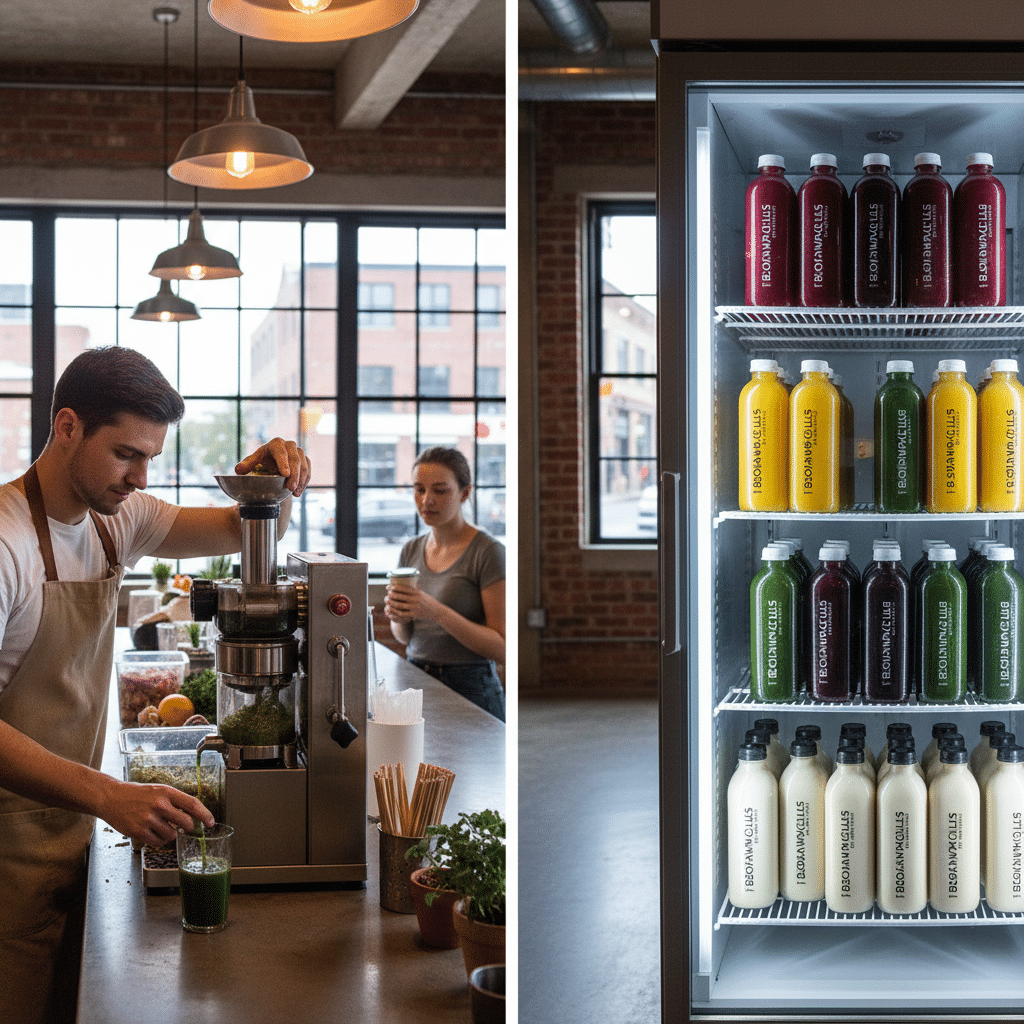

Modern grocery retail is moving away from purely transactional models toward experiential shopping. For supermarket operations managers and retail buyers, the challenge is combating the commoditization of the produce section. A live sugarcane juicing station offers a high-margin solution that capitalizes on the “fresh” trend while introducing visual theatre that disrupts shopper autopilot.

Unlike pre-packaged beverages, live extraction validates the freshness claim immediately. This article outlines the operational requirements, equipment specifications, and profitability factors involved in deploying commercial sugarcane juicers in a retail environment.

The Business Case: Margins and Impulse Buys

The primary driver for installing in-store juicing equipment is the significant markup potential between raw produce and finished beverage. Sugarcane is particularly advantageous compared to citrus or vegetable blends due to its low raw material cost and high yield.

Profitability Drivers

- Low Input Cost: Raw sugarcane stalks are generally inexpensive when sourced in bulk compared to the volume of juice they yield.

- Premium Pricing: Consumers perceive fresh-pressed juice as a premium product, allowing for price points significantly higher than pasteurized alternatives.

- Zero Additives: The product requires no added sugar or preservatives, appealing to health-conscious demographics without additional inventory costs.

Visual Theatre: Leveraging the Process to Sell

In a crowded retail environment, static displays often blend into the background. A live juicing station acts as a dynamic point of interest. The concept of “visual theatre” in retail suggests that showing the manufacturing process creates a perception of higher value and hygiene.

For sugarcane specifically, the extraction process is visually distinctive. The crushing of hard stalks into liquid creates a sensory experience—the sound of the motor, the sight of the cane being crushed, and the immediate flow of juice—that triggers impulse purchases. Placing these stations near the entrance or high-traffic produce end-caps maximizes this conversion rate.

Operational Requirements and Setup

Integrating a manufacturing process into a retail floor requires careful planning regarding space, utilities, and workflow.

1. Space and Footprint

Commercial sugarcane juicers are surprisingly compact, but the station requires more than just the machine footprint. You must account for:

- Input Storage: Space for raw cane stalks (often kept on ice or refrigerated for visual appeal).

- Waste Management: Sugarcane produces a high volume of fibrous waste (bagasse). An integrated chute leading to a large, concealed under-counter bin is essential to maintain a clean appearance.

- Serving Area: Space for cups, lids, and ice.

2. Power and Utilities

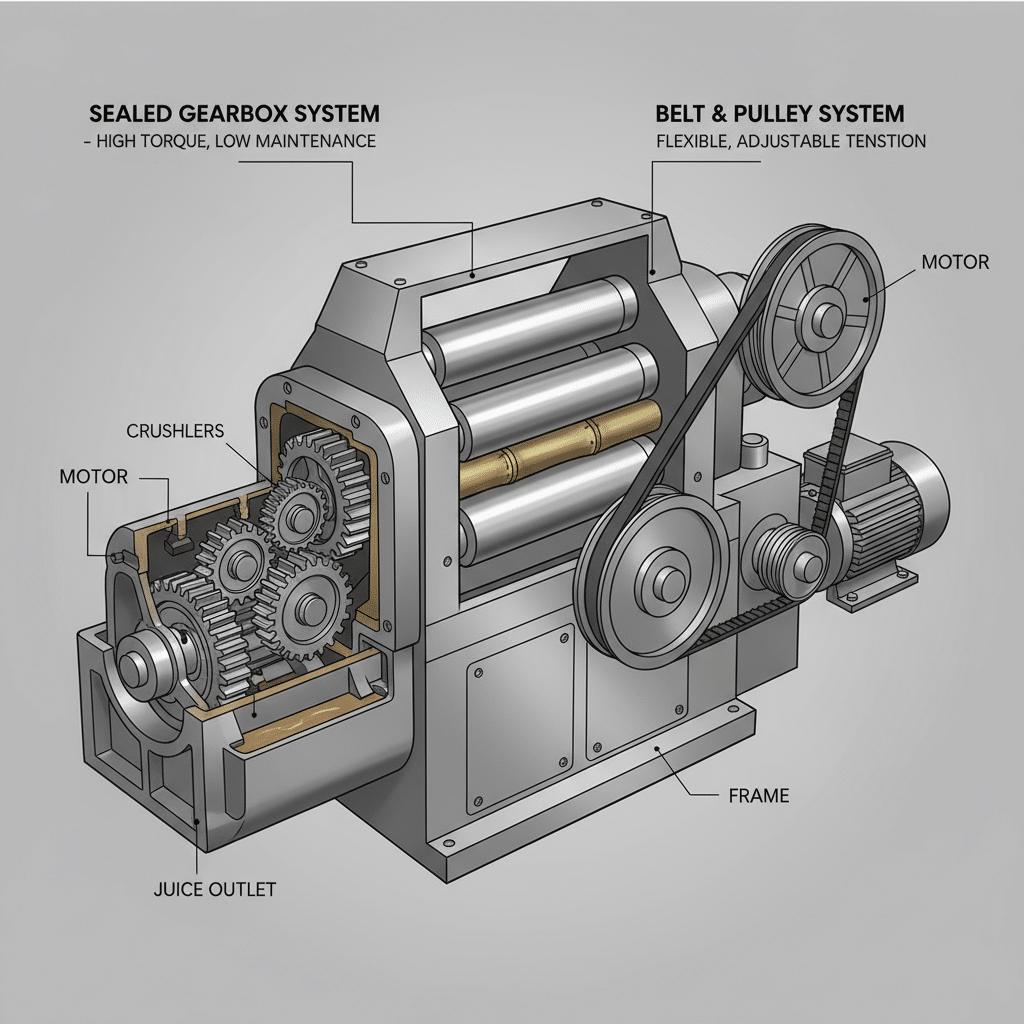

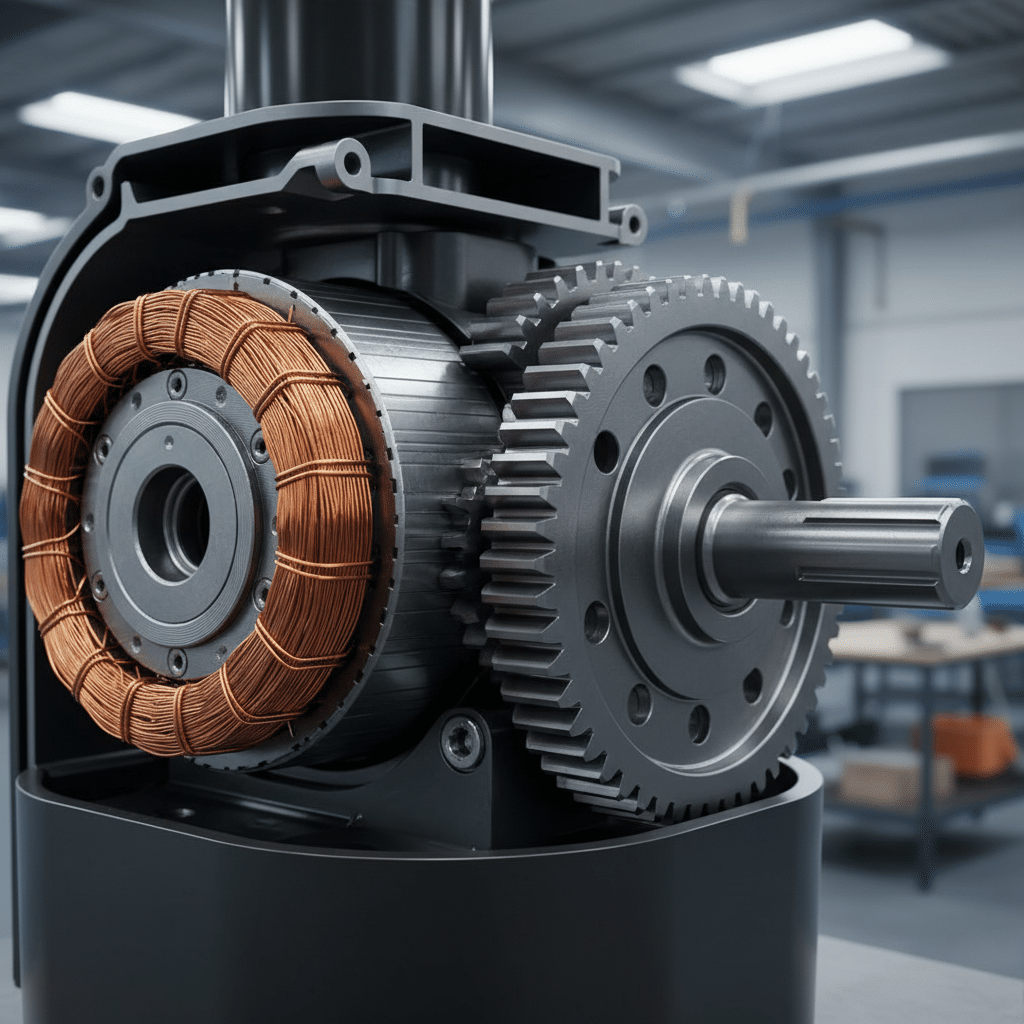

Unlike standard citrus juicers, sugarcane extractors require high torque to crush fibrous stalks. Ensure your electrical infrastructure can handle heavy-duty motors (often 0.5 HP to 1 HP) without tripping breakers, especially if multiple machines share a circuit. Most commercial units run on standard voltage, but verifying amperage requirements is critical.

3. Hygiene and Maintenance

Live processing introduces food safety considerations. Equipment must be NSF-certified or equivalent for food contact. Look for machines with:

- Removable Rollers: The crushing rollers must be easy to detach for daily deep cleaning.

- Stainless Steel Construction: Grade 304 stainless steel is the industry standard for corrosion resistance and ease of sanitation.

- Closed Loop Systems: To prevent contamination and ensure safety, the juicing mechanism should be fully enclosed during operation.

Selecting the Right Equipment

When procuring machines for a supermarket chain, durability and safety are the top specifications. Consumer-grade models will fail under the continuous load of a retail environment.

Key Specifications for Retail Buyers

| Feature | Requirement | Why it Matters |

|---|---|---|

| Roller Material | Solid Stainless Steel | Prevents rust and withstands high crushing pressure without deformation. |

| Safety Mechanism | Emergency Stop & Enclosed Feed | Protects staff and customers; critical for insurance and liability. |

| Throughput | 300-500 kg/hr capacity | Ensures the machine can handle peak hours without overheating. |

| Reverse Function | Standard Requirement | Allows operators to clear jams instantly without dismantling the machine. |

Sourcing and Supply Chain Considerations

The success of the station depends on a consistent supply of quality cane. Retail managers must decide between:

- Pre-peeled Cane: Reduces labor at the store level and improves hygiene appearance but has a shorter shelf life and higher procurement cost.

- Whole Stalks: Cheaper and longer shelf life, but requires staff to scrape/clean the cane before juicing, adding labor hours and potential mess.

Most high-volume supermarkets opt for pre-cleaned, vacuum-packed cane to streamline operations and minimize in-store prep work.

Frequently Asked Questions (FAQs)

What is the shelf life of fresh sugarcane juice?

Fresh sugarcane juice oxidizes quickly, changing color and taste within 15–30 minutes at room temperature. It is strictly a “make-to-order” product unless immediate refrigeration and lemon/lime (which delays oxidation) are used. For retail, the on-demand model is recommended to reduce shrinkage.

How much noise does a commercial sugarcane juicer make?

Modern gear-box driven machines are relatively quiet (often under 70dB), allowing for conversation. However, older chain-driven models can be noisy. Check the decibel rating if the machine is placed near checkout counters.

How do we handle the waste (bagasse)?

Bagasse volume is significant. It is organic and compostable. Some stores partner with local farms or composting facilities to dispose of the fiber, marketing this as a sustainability initiative.

What are the cleaning requirements?

The sugar content makes the machine sticky and attractive to pests if not cleaned rigorously. A wash-down cycle should be performed every 4 hours, with a full disassembly and sanitization at the end of every shift.

Is operator training difficult?

Modern machines are designed with “feed-and-go” safety features, requiring minimal skill. Training primarily focuses on hygiene protocols and machine assembly/disassembly for cleaning.

Next Steps for Implementation

Adding a live sugarcane juicing station transforms a passive produce section into an active revenue generator. By selecting heavy-duty, safety-compliant equipment and planning for the unique waste and supply chain needs of sugarcane, supermarkets can drive significant impulse sales.

Ready to explore equipment options? Contact our team to discuss capacity requirements and request a quote for commercial-grade juicing solutions tailored to high-traffic retail environments.