Turning Process into Profit: The Front-of-House Shift

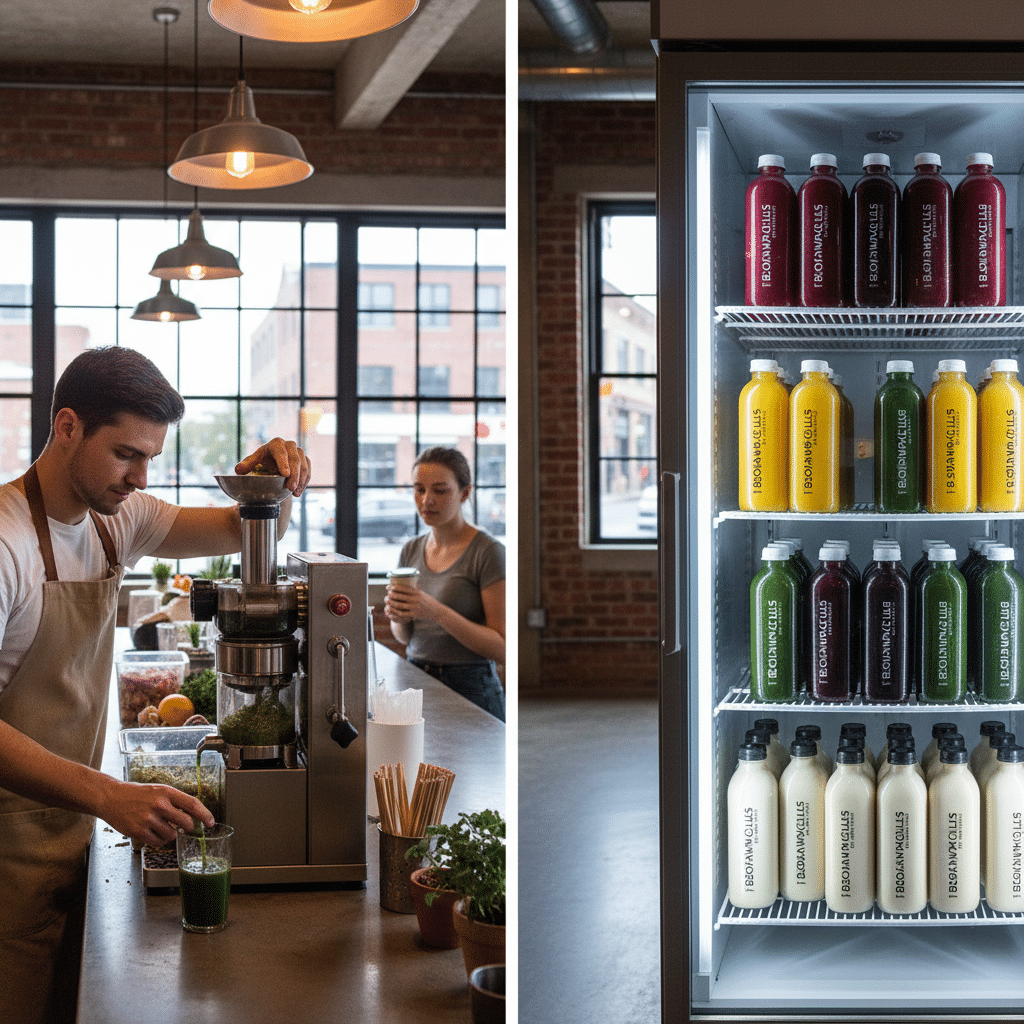

In the competitive beverage industry, the barrier between production and consumption is disappearing. Historically, commercial juicing—particularly for tough ingredients like sugarcane—was relegated to back-of-house kitchens due to noise, mess, and the industrial appearance of the machinery. Today, the trend has inverted. Operators are moving preparation to the front counter, transforming juice extraction from a hidden chore into a visual sales driver.

For B2B buyers, including juice bar owners, hospitality procurement managers, and food retail designers, this shift requires a strategic approach to equipment selection and station layout. A well-designed front-of-house (FOH) station does more than make juice; it leverages the “theater” of preparation to validate freshness, build trust, and trigger impulse purchases.

The Psychology of Transparent Preparation

Consumers are increasingly skeptical of pre-packaged beverages and hidden preparation methods. “Live juicing” addresses this skepticism by offering total transparency. When a customer watches a stalk of sugarcane being crushed and the juice flowing instantly into a cup, the value proposition is immediate and undeniable.

Building Trust Through Visibility

Transparent equipment designs allow customers to inspect the hygiene and freshness of the product without asking a single question. A machine featuring a clear viewing window or a transparent chassis demonstrates that the raw ingredients are natural and the rollers are clean. This visual proof is often more persuasive than any “100% Natural” label.

Triggering Impulse Buys

Impulse purchasing is driven by sensory cues. A static menu board relies on reading; a live juicing station relies on sight and sound. The rhythmic crushing of sugarcane and the vibrant color of the juice create a sensory hook. By placing an aesthetic, transparent machine on the counter, operators convert passive foot traffic into active customers who are drawn in by the activity.

Selecting Equipment for Front-of-House Operations

Not all commercial juicers are suitable for the countertop. Moving equipment FOH introduces new constraints regarding aesthetics, noise, and safety. When sourcing sugarcane machines for display, prioritize the following specifications:

1. Aesthetic and Material Finish

The machine is now part of the interior design. Industrial cast iron or painted metal often looks out of place in modern cafes or hotel buffets.

- Preferred Material: Food-grade Stainless Steel 304. It offers a sleek, professional appearance, resists corrosion from acidic juices, and is easy to polish.

- Transparency: Look for models with polycarbonate or tempered glass viewing windows that showcase the roller mechanism safely.

2. Acoustic Engineering

Noise pollution can ruin the customer experience. A machine running at 80dB+ will disrupt conversation and annoy staff. High-quality FOH juicers utilize precision-machined gearboxes and insulated motor housings to operate quietly, typically under 65-70dB, allowing the machine to run continuously without becoming a nuisance.

3. Safety and Hygiene

Open-roller machines are generally prohibited in customer-facing areas due to injury risks. FOH machines must be fully enclosed. Additionally, the design should prevent juice splatter. A sealed juicing compartment ensures the counter remains sticky-free, which is critical for maintaining a premium image.

Layout Tips for Maximizing the “Theater”

Placing a machine on a counter is not enough. The station layout must facilitate workflow while maximizing visibility.

The “Zone of Attention”

Position the juicer at eye level or slightly below, within the customer’s immediate line of sight upon entry. Avoid placing it behind high sneeze guards or POS terminals that obstruct the view of the extraction process. The movement of the machine should be visible from the queue.

Workflow Efficiency

Speed of service is critical for impulse sales—customers will not wait long for a “convenience” drink. Design the workflow to minimize operator movement:

- Input Zone: Keep pre-washed, pre-cut sugarcane stalks in a clean, chilled display vessel next to the machine.

- Processing Zone: The machine sits centrally. Ensure the waste chute feeds directly into an under-counter bin to hide the fibrous bagasse immediately.

- Output Zone: Cups, ice, and garnishes should be within arm’s reach of the juice spout to ensure a pour-to-serve time of under 30 seconds.

Lighting and Signage

Use focused track lighting to illuminate the machine and the fresh ingredients. Warm light enhances the natural color of sugarcane juice. Simple signage such as “Pressed Fresh on Order” reinforces the visual narrative.

Manufacturing and Quality Considerations

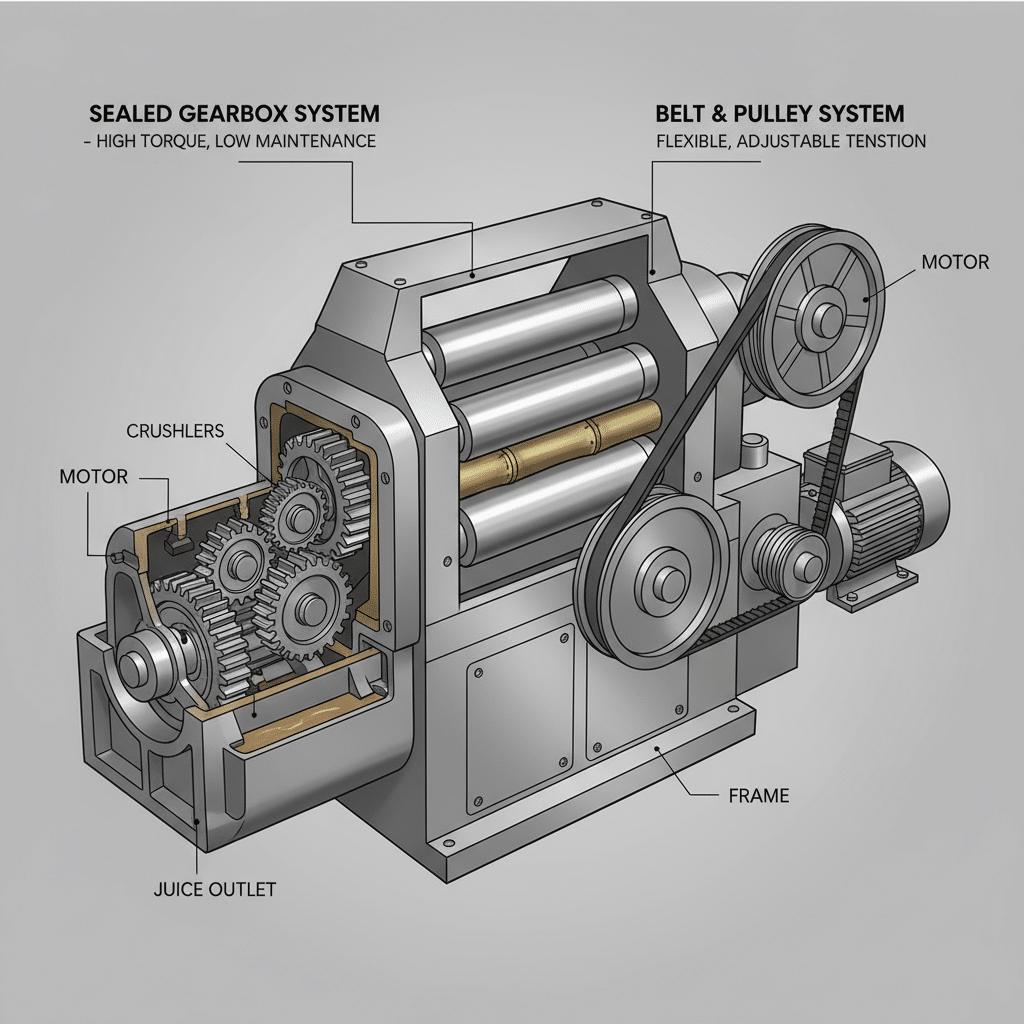

For distributors and procurement officers, vetting the manufacturing quality of FOH machines is essential to prevent downtime and reputational damage.

| Component | What to Look For | Why It Matters |

|---|---|---|

| Rollers | Solid Stainless Steel 304 | Durability against hard cane fibers; prevents metal shavings/contamination. |

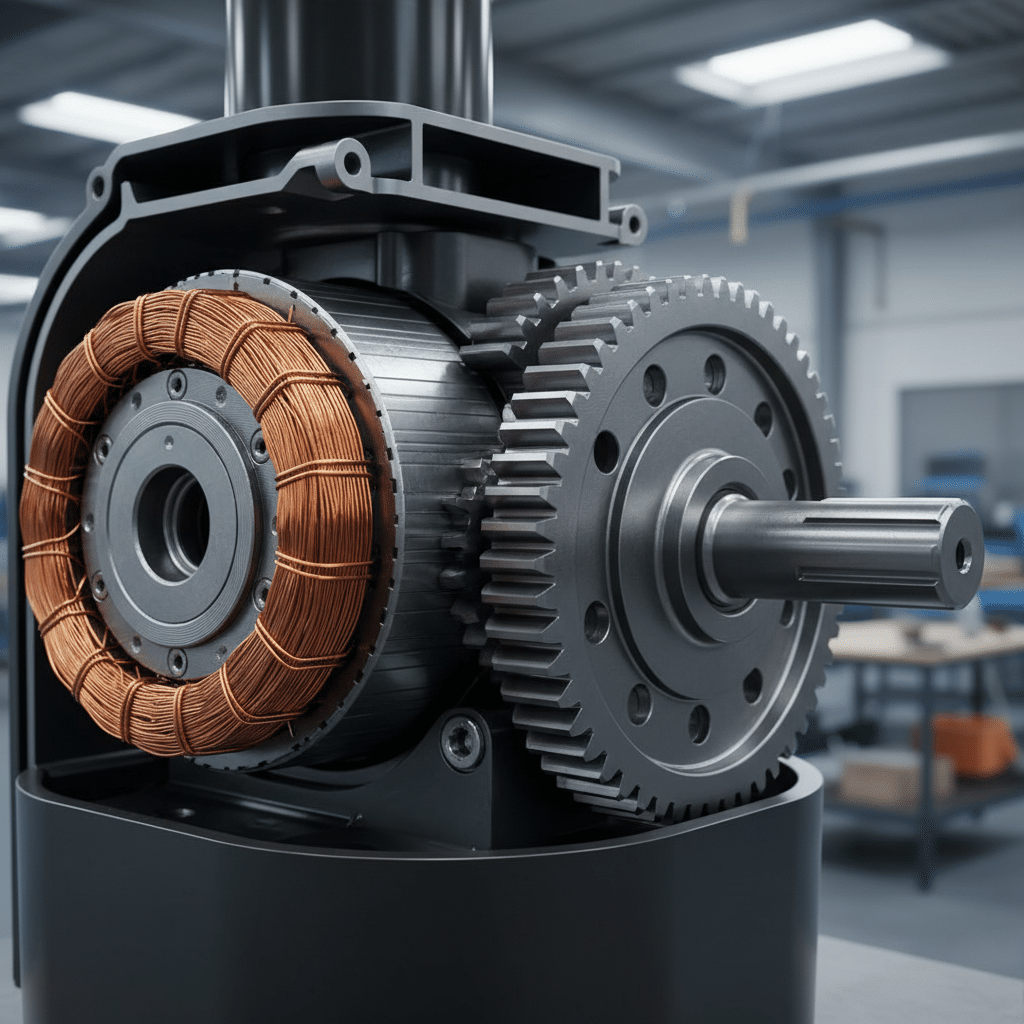

| Motor | Copper winding, high torque | Ensures consistent crushing power without overheating during peak hours. |

| Chassis | Reinforced frame | Reduces vibration and movement on the counter. |

| Seals | Double-sealed bearings | Prevents juice from leaking into the motor compartment (a common failure point). |

Buying Guide: Sourcing Your Station Equipment

When requesting quotes for live juicing equipment, consider the following logistics and customization options:

- Customization (OEM/ODM): If you are a franchise or brand, ask if the manufacturer can customize the machine housing color or apply laser-etched logos to align with your store aesthetic.

- Spare Parts Availability: Ensure the supplier provides a kit of common wear parts (gaskets, fuses) to avoid downtime.

- Cleaning Protocols: Ask for a demonstration of the cleaning process. FOH machines must be cleaned frequently; a system that requires tools to disassemble is impractical for busy staff. Look for “tool-free” removal of rollers and juice trays.

- Certifications: Verify that the equipment meets local electrical safety and sanitation standards (e.g., CE, ETL, or NSF equivalent where applicable).

Frequently Asked Questions

How much space does a commercial sugarcane juicer require?

Compact countertop models typically require a footprint of approximately 40cm x 50cm (16″ x 20″). However, you should allocate an additional 30cm (12″) on either side for ingredient handling and airflow.

Is live juicing noisy?

It depends on the machine. Industrial models are loud, but modern FOH-specific units are designed with noise reduction technology. Always check the decibel (dB) rating in the spec sheet; aim for <70dB.

How often should the machine be cleaned?

For hygiene and visual appeal, the external surfaces should be wiped down constantly. The internal juicing components should be rinsed every few hours (or per local health code) and deep cleaned at the end of every shift.

Can these machines handle different sizes of sugarcane?

Yes, most professional machines have self-adjusting rollers or a feed inlet designed to accommodate standard cane diameters (usually up to 50mm). For very thick cane, splitting it in half may be required depending on the motor power.

What is the typical ROI for a live juicing station?

While variable, the margin on sugarcane juice is typically high due to low raw material costs. Adding the “live” element often allows operators to charge a premium for freshness, shortening the payback period for the equipment.

Enhance Your Beverage Service

Implementing a live juicing station is a strategic investment in customer experience and sales volume. By choosing equipment that balances industrial durability with retail aesthetics, you create a focal point that drives revenue.

Ready to upgrade your front-of-house operations?