In the commercial beverage equipment industry, the transmission system is the heart of any sugarcane juicer. Unlike soft fruits, sugarcane is a fibrous, tough stalk that offers significant resistance during crushing. For B2B buyers—ranging from equipment distributors to procurement managers for juice bar franchises—choosing the right transmission technology is critical for operational efficiency and machine longevity.

The debate often settles on two primary technologies: Gearbox (Direct Drive) systems and Belt or Chain Drive systems. While both can extract juice, their performance under heavy loads, maintenance requirements, and total cost of ownership differ significantly.

This guide analyzes the technical differences between these systems to help you source equipment that minimizes downtime and maximizes torque.

The Role of Torque in Sugarcane Juicing

Before comparing the mechanisms, it is essential to understand the physics of juicing sugarcane. To extract maximum yield from a dry, fibrous stalk, the rollers must apply immense pressure at relatively low rotational speeds (RPM). High speed often leads to friction heat, which can spoil the juice flavor, and lower extraction rates.

Therefore, the transmission system’s primary job is speed reduction and torque multiplication. The motor spins fast, but the rollers must turn slowly with high force. How the machine achieves this reduction defines its reliability.

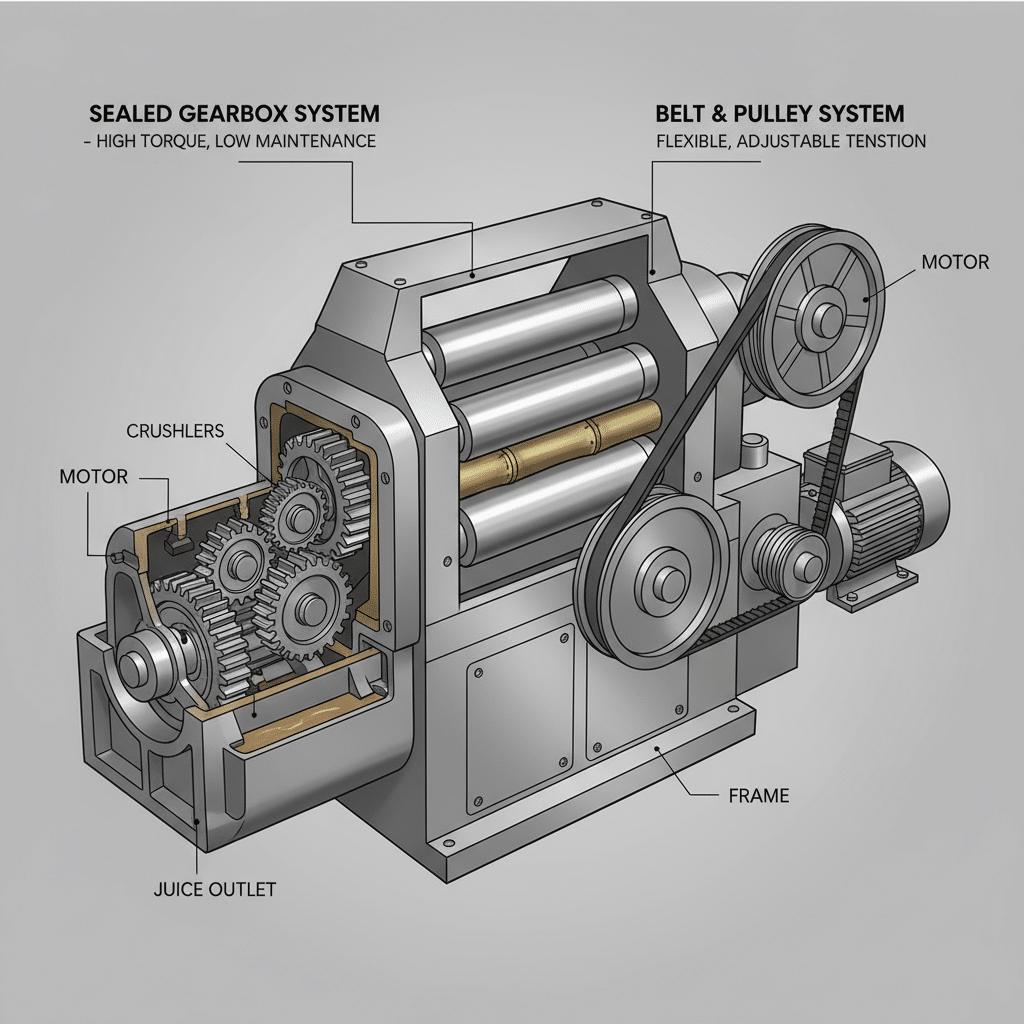

1. Gearbox Transmission (Direct Drive)

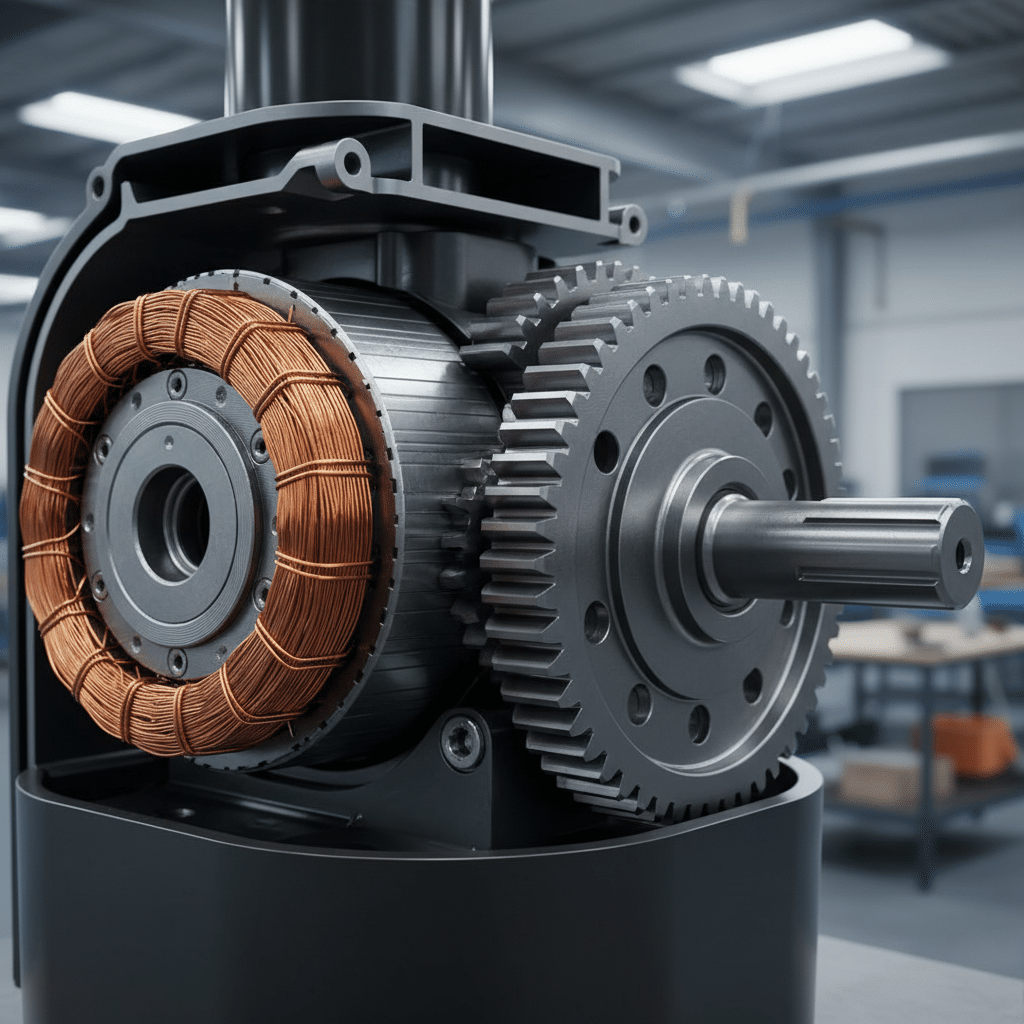

In a gearbox-driven system, the electric motor is connected directly to a gear reduction box (often worm gears or helical gears), which then drives the rollers. This is the standard for modern, heavy-duty commercial machines.

Advantages

- High Torque Efficiency: Gearboxes provide a direct transfer of power with minimal energy loss. This ensures that even the thickest, hardest cane stalks are crushed without the machine stalling.

- Zero Slippage: Unlike belts, gears have interlocking teeth. There is no risk of the transmission slipping under heavy load, ensuring consistent throughput.

- Low Maintenance: Gearboxes are typically sealed units lubricated for life or requiring infrequent oil changes. There are no belts to tension or replace.

- Hygiene & Safety: Being fully enclosed, gearboxes do not generate rubber dust (from wearing belts) and are easier to clean around, a crucial factor for food safety compliance.

Considerations

- Initial Cost: Precision-machined gears and sealed housings are more expensive to manufacture than pulleys and belts.

- Weight: These machines tend to be heavier, which is often a sign of stability but can impact shipping logistics.

2. Belt and Chain Drive Systems

Belt and chain drives connect the motor to the rollers via pulleys and sprockets. While common in older designs or entry-level machinery, they present distinct characteristics for industrial use.

Advantages

- Shock Absorption: Belts have a slight elasticity. If a rock or metal object accidentally enters the rollers, the belt may slip, potentially saving the motor or rollers from catastrophic damage (acting as a sacrificial fuse).

- Lower Manufacturing Cost: These systems are generally cheaper to produce, resulting in a lower purchase price for budget-conscious markets.

- Repairability: Replacing a snapped belt is often simpler and requires less technical skill than repairing a damaged gearbox.

Considerations

- Slippage & Power Loss: Under heavy load (e.g., high-fiber cane), belts can slip, causing the rollers to stop while the motor spins. This reduces efficiency and throughput.

- High Maintenance: Belts stretch over time and require regular tensioning. Chains require lubrication, which can attract dust and bagasse fibers, creating a hygiene risk.

- Noise and Vibration: Chain drives, in particular, can be noisier than precision gearboxes.

Comparative Analysis: Gearbox vs. Belt Drive

| Feature | Gearbox (Direct Drive) | Belt/Chain Drive |

|---|---|---|

| Torque Transfer | High (Direct, no slip) | Moderate (Risk of slip) |

| Maintenance | Low (Sealed system) | High (Tensioning, greasing) |

| Durability | Excellent for heavy duty | Moderate (Wear parts) |

| Hygiene | High (Enclosed) | Medium (Debris accumulation) |

| Noise Level | Low / Smooth | Variable / Higher |

| Initial Cost | Higher | Lower |

Why Gearboxes are Preferred for Heavy-Duty B2B Applications

For B2B buyers supplying busy juice bars, hotels, or supermarkets, reliability is the most critical metric. A machine that is down for belt tensioning or one that jams on thick cane costs the operator revenue.

The “No-Slip” Requirement

Commercial operators cannot afford to stop and reverse machines constantly because a belt slipped on a tough stalk. Gearbox systems power through fiber variations consistently. This consistency is vital for standardized processes in franchise operations.

Hygiene and Contamination Risks

In food processing, particulate matter is a major concern. Belt drives degrade over time, creating fine rubber dust. If the transmission area is not perfectly isolated from the juice extraction zone (which is difficult in open-frame belt designs), this poses a contamination risk. Sealed gearboxes eliminate this variable entirely.

Manufacturing & Quality Assurance

When sourcing these machines, it is important to inquire about the manufacturing standards of the transmission system.

- Gear Material: Look for hardened steel or high-grade alloys. Plastic or nylon gears inside the box are suitable only for light home use, not commercial environments.

- Seals and Bearings: High-quality seals prevent lubricant leakage and protect the gears from juice ingress, which is acidic and corrosive.

- Motor Integration: Ensure the motor is rated for the gearbox’s torque capacity. A powerful motor with a weak gearbox will strip gears; a weak motor with a strong gearbox will stall.

Buying Guide for Distributors

If you are importing or distributing sugarcane machines, consider these factors to reduce warranty claims and improve customer satisfaction:

1. Ask for Transmission Specs

Do not just look at motor power (HP/Watts). Ask the manufacturer for the reduction ratio and the rated torque at the roller shaft.

2. Spare Parts Availability

For belt-driven units, you must stock replacement belts and chains. For gearbox units, stock is generally lower, but you may need full gearbox assemblies for rare catastrophic failures.

3. Customization & MOQ

Manufacturers can often adapt the transmission housing or motor voltage (110V/220V, 50Hz/60Hz) to suit your local market. Confirm Minimum Order Quantities (MOQ) for customized builds, especially if you require specific gear ratios for different cane varieties (soft vs. hard cane).

FAQs: Transmission Systems

Which system is better for hard sugarcane varieties?

The gearbox system is superior for hard cane. Its direct drive capability ensures maximum torque is applied to crush hard fibers without slipping.

Do gearbox machines require oil changes?

Most modern commercial gearbox juicers are sealed for life or require oil changes only after several years of intense usage. Always check the user manual for specific intervals.

Why are belt-driven machines cheaper?

Belts and pulleys are standard, off-the-shelf components that do not require the precision machining and assembly of a sealed gearbox, reducing manufacturing costs.

Can a belt drive system handle commercial volume?

Yes, but it requires more maintenance. Operators must be trained to check belt tension regularly to prevent slipping and premature wear.

What happens if a gearbox machine jams?

Quality machines feature a reverse switch. Because there is no belt to slip, the reverse function instantly disengages the jammed stalk. Most motors also have thermal overload protection to prevent burnout.

Conclusion

While belt-driven machines offer a lower entry price, the gearbox (direct drive) transmission is the industry standard for professional, high-volume sugarcane juicing. Its ability to deliver consistent torque, maintain hygiene, and operate with minimal maintenance makes it the superior choice for B2B buyers focused on long-term value and customer satisfaction.

Ready to upgrade your equipment inventory? Contact us today to discuss specifications, request a quote, or order a sample of our heavy-duty gearbox sugarcane machines.