The Rise of Fresh Juice Bars in Event Catering

In the competitive landscape of event catering, beverage service often dictates guest satisfaction. While alcohol and soft drinks remain staples, there is a growing demand for fresh, wellness-oriented options. Sugarcane juice, known for its natural electrolytes and refreshing taste, has emerged as a popular choice for weddings, corporate retreats, and outdoor festivals.

However, serving fresh sugarcane juice at scale presents unique operational challenges. Unlike pre-mixed beverages, sugarcane juice must be extracted on-site to preserve color and flavor. This requirement places immense pressure on the equipment. For catering businesses and event planners, standard residential juicers are insufficient. Success relies on commercial sugarcane juicers designed specifically for high-volume, continuous operation.

This guide explores the technical and operational requirements for implementing sugarcane juice stations in a catering environment, focusing on speed, motor reliability, and portability.

The High-Volume Challenge: Speed vs. Quality

At a busy wedding reception or a trade show, a juice bar might face a queue of 50 to 100 guests in a short window. Speed is the primary metric of success. A machine that processes one stick of cane every two minutes creates bottlenecks, frustrating guests and wasting service time.

Throughput Capabilities

Commercial-grade extractors are engineered to handle rapid throughput. When evaluating equipment for events, look for the following performance indicators:

- Roller Efficiency: High-quality machines utilize 3-roller or 4-roller systems that extract maximum juice in a single pass. Single-pass extraction is critical for speed; feeding the same cane through multiple times slows down service.

- Output Rates: A viable event machine should produce between 2 to 4 liters (approximately 65–135 oz) per minute. This allows caterers to fill a standard glass in under 10 seconds.

- Instant Reverse Function: Jams can happen, especially with thick or knotted cane varieties. An instant reverse switch allows operators to clear obstructions immediately without dismantling the machine.

Continuous Operation: Preventing Overheating

Perhaps the most critical differentiator between a standard juicer and an event-ready commercial unit is the duty cycle. Residential motors are designed for intermittent use—making a glass or two for breakfast. If pushed to run continuously for an hour, they often overheat and trigger thermal cutoffs, halting operations.

Heavy-Duty Gearboxes and Motors

For catering, the equipment must run for 3 to 5 hours continuously. Buyers should prioritize:

- Gearbox Design: Look for heavy-duty gearboxes that reduce motor strain. Direct-drive systems or high-torque gear reductions allow the motor to crush hard cane without stalling.

- Cooling Systems: Advanced commercial units feature integrated cooling fans or ventilated housings to dissipate heat generated by the motor.

- Motor Power: A minimum of 0.5 HP (370W) is standard for light commercial use, but high-volume event machines often utilize 1 HP to 1.5 HP motors to ensure consistent torque under load.

Portability and Setup for Mobile Caterers

Event planners rarely work in the same location twice. Equipment must be transported to ballrooms, garden marquees, and convention centers. Portability is a logistical necessity.

Weight vs. Durability Trade-offs

Commercial sugarcane juicers are inherently heavy due to the stainless steel rollers and powerful motors required to crush cane. However, design features can mitigate transport issues:

- Tabletop Models: These compact units typically weigh between 40kg and 60kg. They require two staff members to lift but fit easily into catering vans.

- Cart-Mounted Units: Some manufacturers offer machines integrated into wheeled carts. While bulkier, these eliminate the need for lifting and provide built-in waste storage.

- Battery-Operated Options: For outdoor weddings or beach events where power outlets are scarce, battery-powered commercial juicers are becoming increasingly relevant. These units usually offer 2–4 hours of operation on a single charge, providing flexibility in floor plan design.

Hygiene and Aesthetics in Front-of-House Service

In catering, the visual appeal is part of the service. Sugarcane juicing is often treated as “live station” entertainment. The equipment must look professional and adhere to strict hygiene standards.

Material Specifications

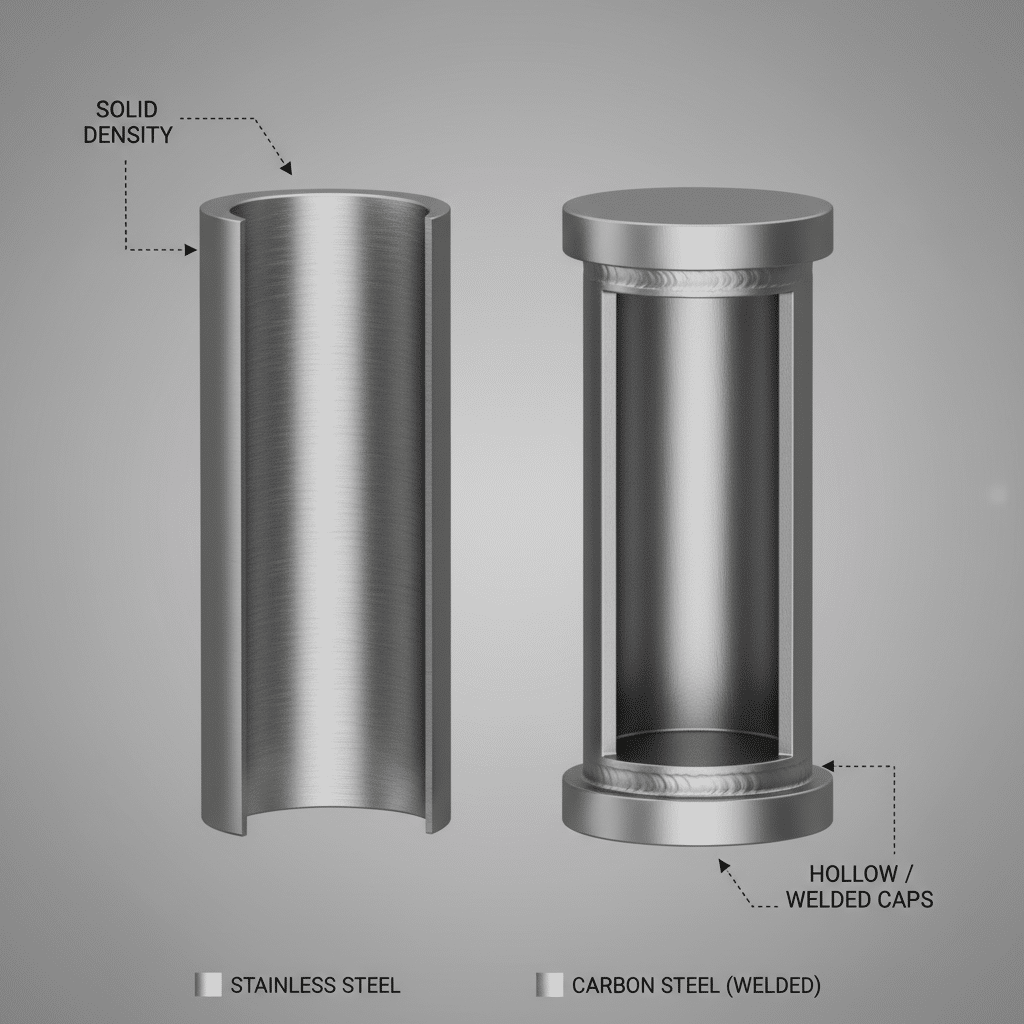

- Food-Grade Stainless Steel (SS304): The rollers and all juice-contact parts must be made of SS304 stainless steel. This material resists corrosion from the acidic juice and is easy to sanitize.

- Transparent Housings: Many event-focused machines feature clear polycarbonate covers. This allows guests to see the crushing process (adding to the theater) while keeping hands safe and preventing dust or insects from entering the mechanism.

- Closed-Loop Waste Disposal: Piles of crushed cane (bagasse) can look messy and attract bees. Professional catering machines often have chutes that direct waste directly into a concealed bin under the counter, maintaining a clean station appearance.

Buying Guide: Key Considerations for Procurement

When sourcing commercial sugarcane juicers for a catering inventory, consider the following factors to ensure a return on investment.

1. Power Requirements

Ensure the voltage matches the region of operation (e.g., 110V vs. 220V). For international caterers, dual-voltage capability or confirming the plug type with the manufacturer is essential.

2. Maintenance and Cleaning

Events finish late, and staff are tired. Machines that require complex tools to disassemble for cleaning will likely be maintained poorly. Look for “easy-clean” designs where the roller compartment can be flushed with water or where rollers are easily removable without specialized tools.

3. Noise Levels

A loud industrial motor can disrupt speeches or ambient music. Look for machines advertised as “silent” or “low noise,” typically achieved through precision-machined gears and insulated casings.

4. Safety Features

With temporary staff often operating equipment, safety is paramount. Essential features include:

- Emergency Stop Buttons: Prominently placed for quick access.

- Feed Inlets: Designed to accept cane but too narrow for fingers.

- Overload Protection: Circuit breakers that trip to protect the motor rather than burning it out.

Summary

Integrating fresh sugarcane juice into a catering menu offers a high-margin, premium beverage option that appeals to health-conscious guests. However, the success of this service relies entirely on the equipment’s ability to handle high volumes without failure. By investing in heavy-duty, continuous-operation machines with portability features, caterers can deliver a seamless experience that enhances their brand reputation.

Ready to upgrade your event beverage capabilities? Contact us today to discuss commercial sugarcane juicer options tailored for high-volume catering.