Minimize Downtime and Maximize Yield

In a high-volume commercial environment, a sugarcane juicer is a critical asset. Unlike standard fruit juicers, these machines operate under immense torque to crush fibrous stalks. Consequently, operational issues such as jamming, misalignment, or mechanical noise can immediately halt production and impact revenue.

Understanding the mechanical stress points of your equipment is the first step toward prevention. This guide addresses the most frequent technical issues operators face with commercial sugarcane extractors and provides actionable protocols for troubleshooting and maintenance.

Diagnosing Common Operational Failures

Most sugarcane juicer malfunctions stem from three core areas: feed rate inconsistencies, roller misalignment, or lack of lubrication. Below are the standard procedures for diagnosing and resolving these issues.

1. Machine Jamming and Stalling

Jamming is the most common complaint in commercial settings. It typically occurs when the motor torque is insufficient for the diameter or hardness of the cane being processed.

- Cause: Feeding cane that is too thick, feeding multiple stalks simultaneously, or using dry, hardened cane.

- Immediate Fix: Stop the machine immediately. If your model has a reverse switch, engage it to back the stalk out. Do not force the cane through. If no reverse function exists, power down, unplug the unit, and manually rotate the rollers (if accessible) or disassemble the housing to clear the blockage.

- Prevention: Split thick stalks (typically those over 30mm, depending on machine specs) vertically before feeding. Cut cane ends at an angle to help the rollers grip the material gradually rather than hitting a blunt wall of fiber.

2. Unusual Grinding Noises or Vibration

Commercial juicers are heavy-duty, but they should run relatively smoothly. New noises usually indicate internal friction or loose components.

- Cause: Worn bearings, lack of gear lubrication, or chain slack (in chain-driven models).

- Diagnosis:

- High-pitched squealing: Usually indicates dry bearings or metal-on-metal contact. Lubrication is required.

- Rhythmic clunking: Often points to a loose chain or a damaged gear tooth.

- Vibration: Check that the machine is on a level surface and that the mounting bolts securing the motor and roller assembly are tight.

- Action: Apply food-grade grease to gears and chains according to the manufacturer’s schedule. If bearings are sealed and noisy, they likely need replacement.

3. Poor Juice Extraction (Low Yield)

If the bagasse (crushed cane waste) comes out wet, the machine is not applying sufficient pressure.

- Cause: Incorrect gap spacing between the rollers. Over time, vibration can loosen the adjustment knobs.

- Fix: Tighten the roller gap adjustment knobs. This should be done incrementally. Both sides must be tightened equally to ensure the roller remains parallel. If the roller is crooked, it will cause uneven wear on the bearings and poor extraction on one side.

Preventative Maintenance Protocol

Sugarcane juice has a high sugar content, which becomes sticky and hardens like cement when dry. This residue is the primary enemy of moving parts.

Daily Cleaning Procedure

Flushing water through the machine is rarely enough. Sugar syrup penetrates seals and accumulates on axles.

- Disassembly: Remove the front panel and juice tray daily.

- Hot Water Flush: Use hot water to dissolve sugar deposits on the rollers.

- Drying: Ensure the machine is dry before reassembly to prevent corrosion, even on stainless steel parts.

Lubrication Schedule

Commercial machines rely on heavy gears and chains. Neglecting lubrication increases amp draw on the motor and leads to burnout.

- Weekly: Inspect chains for tension and apply chain lubricant.

- Monthly: Grease external bearings and gear teeth. Always use food-grade lubricants for any part that has even a remote chance of contacting the juice path, although the drive mechanism should be sealed off from the extraction zone.

Repair vs. Replace: Evaluating Equipment Viability

When facing persistent issues, operators must decide whether to invest in repairs or upgrade to a more robust unit. Consider the following factors:

| Component Failure | Repair Feasibility | Replacement Indicator |

|---|---|---|

| Rollers | High. Rollers can be cleaned or re-knurled in some industrial cases. | If the stainless steel surface is deeply pitted or corroded, compromising hygiene. |

| Motor | Medium. Capacitors can be replaced easily. | If the motor windings are burnt due to repeated stalling/overheating, a new machine is often more cost-effective. |

| Gearbox | Low. Gearbox repairs are labor-intensive. | Cracked casings or stripped gears usually warrant a machine replacement. |

Technical Considerations for New Equipment

If your current equipment requires frequent repairs, it may be undersized for your volume. When sourcing commercial sugarcane juicers, prioritize these specifications:

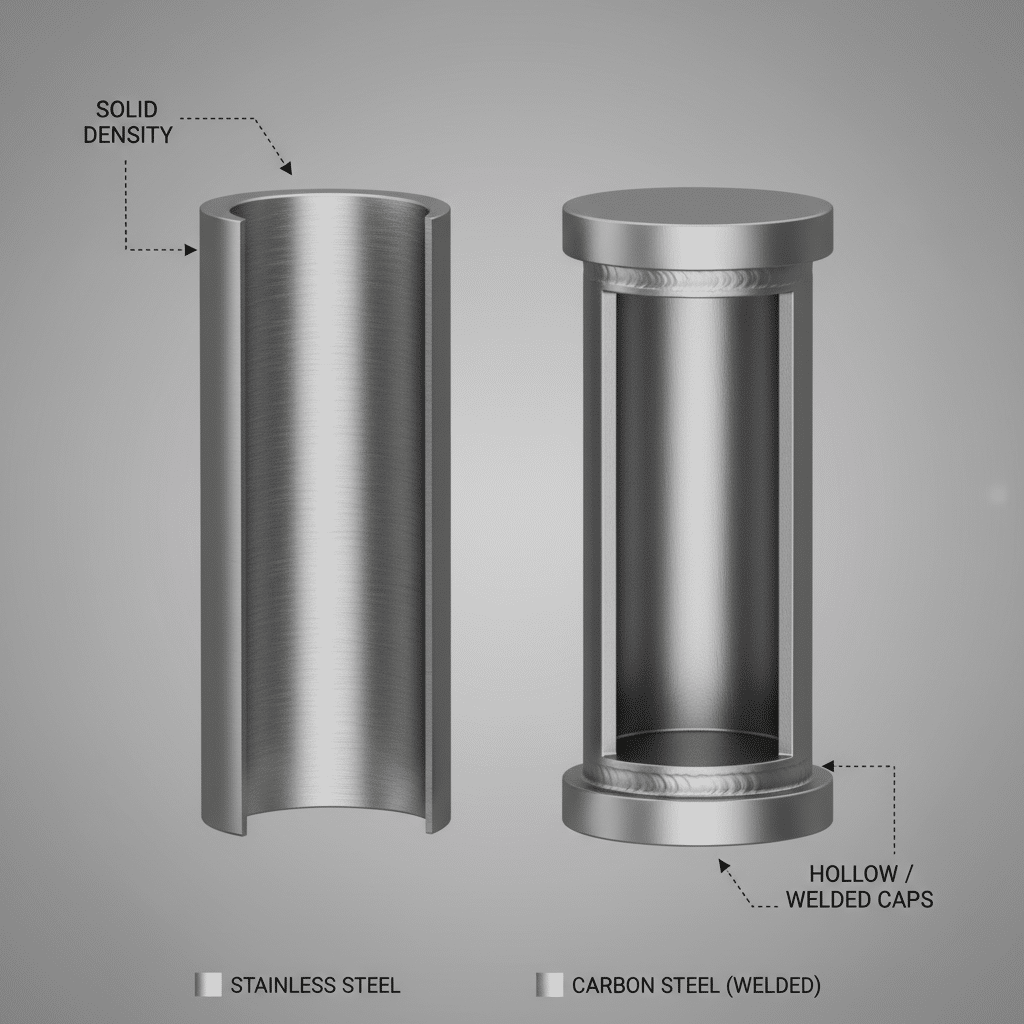

- Roller Material: Ensure rollers are solid 304 Stainless Steel. Inferior plated rollers will flake over time, contaminating the product.

- Gearbox Design: Look for heavy-duty gear reduction systems rather than direct drives or belt drives, which may slip under heavy loads.

- Reverse Function: Essential for clearing jams quickly without disassembly.

- Safety Features: Emergency stop buttons and isolated electrical boxes are standard requirements for industrial safety compliance.

Frequently Asked Questions

Why is my sugarcane juicer leaking oil?

Oil leaks typically originate from the gearbox or seal failure on the roller shafts. If the seals separating the drive mechanism from the juicing compartment fail, stop using the machine immediately to prevent product contamination. Replace the seals and check the shaft for wear.

How often should I sharpen or replace the rollers?

Sugarcane rollers do not typically need “sharpening” like knife blades, but the knurling (grooves) can wear down after years of heavy use, reducing grip. If the machine struggles to pull the cane in, the rollers may need replacement.

Can I process frozen sugarcane?

No. Frozen cane is significantly harder than fresh cane and can shatter gears or bend roller shafts. Always allow cane to thaw completely before juicing.

What causes the motor to hum but not turn?

This often indicates a failed start capacitor or a seized bearing. If the roller moves freely by hand (when unplugged) but the motor won’t start, check the capacitor. If it cannot be moved by hand, a mechanical jam or seized bearing is likely the cause.

Secure Reliable Processing Equipment

Minimizing downtime requires a combination of disciplined maintenance and high-quality machinery. If your current equipment is no longer meeting your production demands, or if you require specific replacement parts, we can assist.

Contact us today to request a quote for commercial-grade sugarcane juicers or to discuss custom manufacturing specifications for your market.