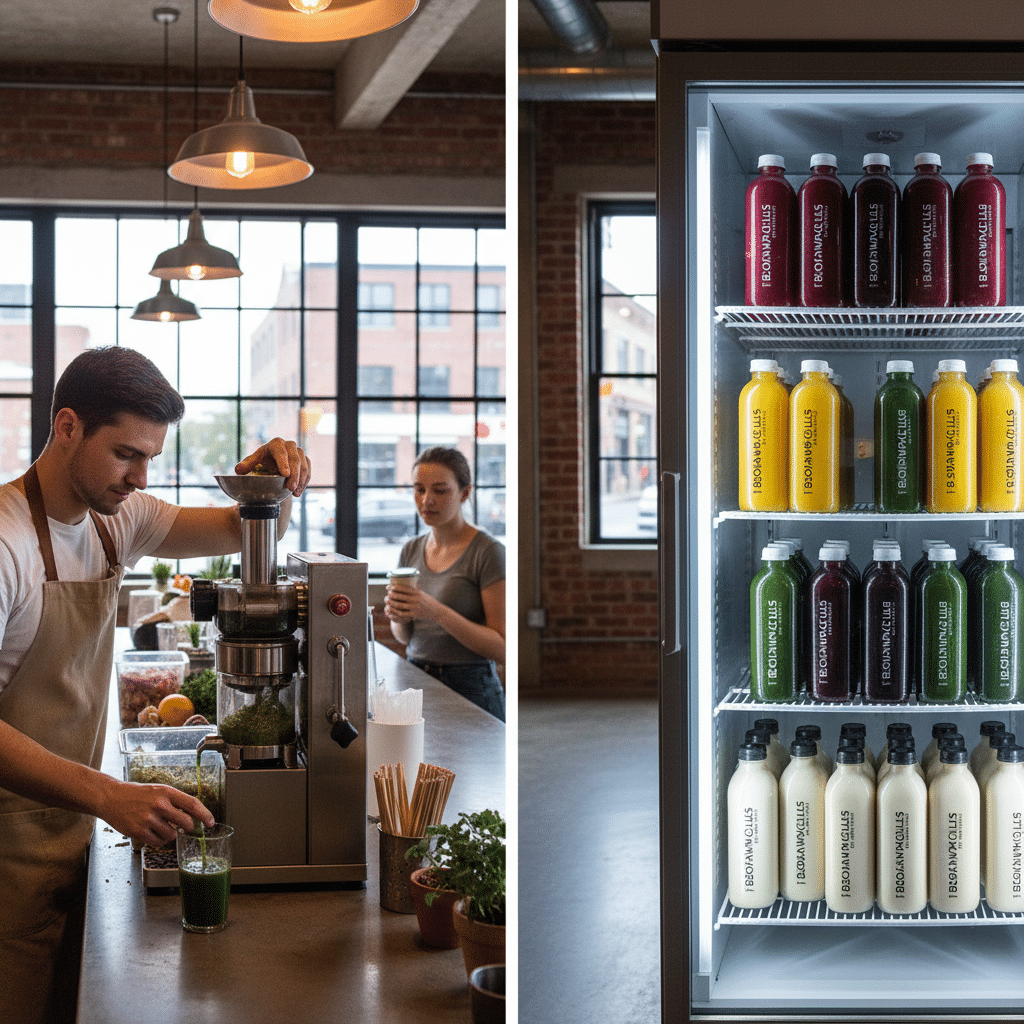

For commercial sugarcane juice businesses and industrial processors, the primary product is the juice, but the primary logistical challenge is often the waste. Sugarcane bagasse—the fibrous residue left after crushing—accounts for approximately 30% to 50% of the cane’s total weight. In high-volume operations, this byproduct accumulates rapidly, creating storage issues, attracting pests, and incurring significant disposal costs.

However, the global shift toward circular economy models has reclassified bagasse from a liability to a valuable resource. Effective bagasse management not only reduces waste hauling fees but can also open new revenue streams or partnership opportunities. This guide outlines practical strategies for B2B operators to manage, dispose of, or repurpose sugarcane bagasse efficiently and sustainably.

The Technical Profile of Bagasse

Understanding the material properties of bagasse is the first step in determining the right disposal channel. Fresh bagasse typically consists of:

- Moisture: 45% to 50% (depending on extraction efficiency).

- Fiber: 40% to 45% (cellulose, hemicellulose, and lignin).

- Soluble Solids: 2% to 5% (residual sugars).

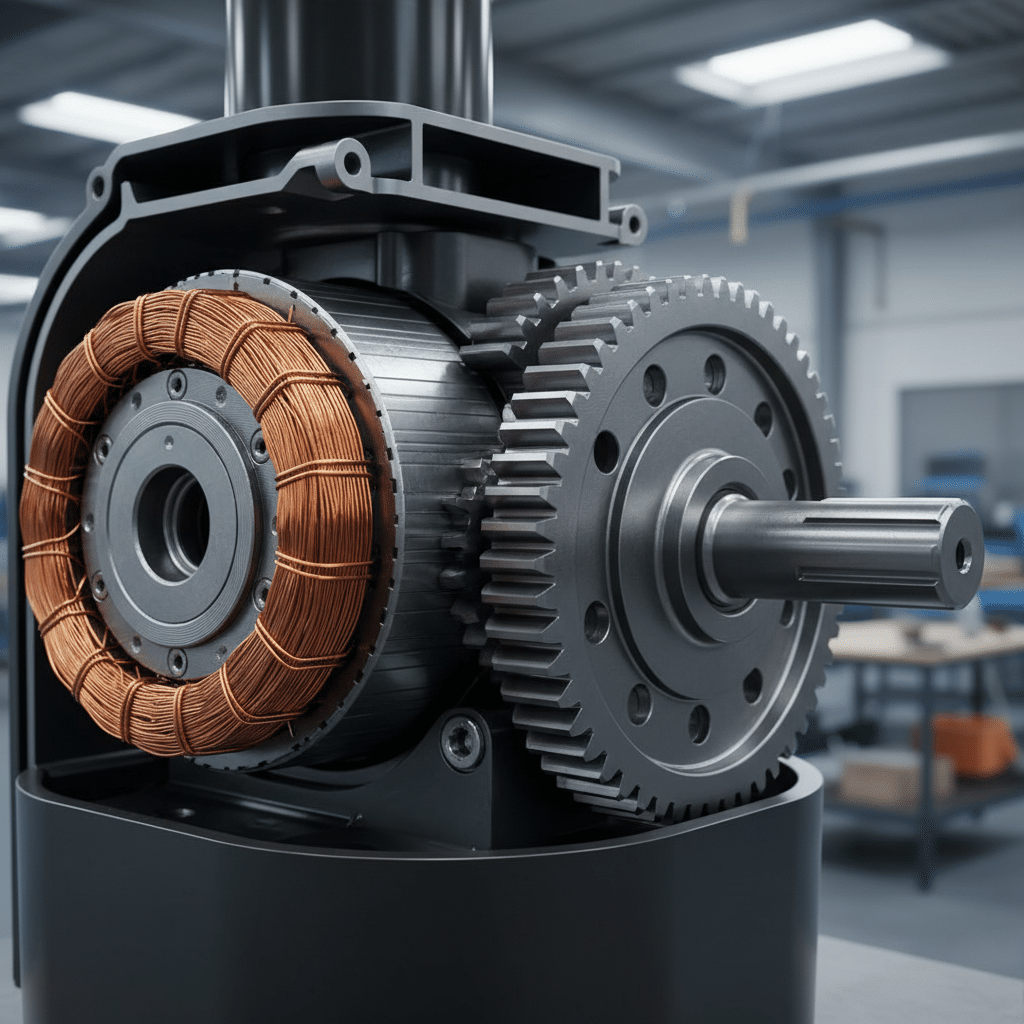

Operational Note: The efficiency of your extraction equipment directly impacts waste management. High-efficiency crushers produce drier bagasse, which is lighter to transport, less prone to rapid fermentation, and more desirable for biomass applications.

Strategic Disposal and Repurposing Options

Businesses generally have three viable pathways for handling bagasse: agricultural integration, energy generation, and raw material supply. The viability of each depends on your location, volume, and local infrastructure.

1. Agricultural Integration: Composting and Animal Feed

For small-to-medium enterprises (SMEs) located near agricultural zones, direct partnership with farms is often the most cost-effective solution.

- Composting and Soil Amendment: Bagasse has a high carbon-to-nitrogen ratio. When composted, it improves soil structure and water retention. Many organic farms accept clean bagasse to mix with nitrogen-rich waste (like manure) to create balanced compost.

- Animal Feed: While fresh bagasse is low in digestibility due to high lignin content, it can be treated (hydrolyzed or fermented) to serve as roughage for ruminants. Partnering with local livestock operations can provide a consistent offtake channel, though feed safety regulations must be verified locally.

2. Biomass and Bioenergy Production

Bagasse is a potent biofuel. In large sugar mills, it is traditionally burned to power the facility. For standalone juice businesses, the opportunity lies in supplying biomass facilities.

- Pelletization: Dry bagasse can be compressed into pellets or briquettes. These have a high calorific value and are used in industrial boilers or residential heating.

- Biogas: Through anaerobic digestion, bagasse can contribute to biogas production. This requires partnership with a specialized waste-to-energy plant.

3. Raw Material for Biodegradable Packaging

The demand for eco-friendly packaging has surged. Bagasse is now a primary material for molded pulp products like disposable plates, bowls, and takeaway containers. While a juice business will not manufacture these products on-site, they can serve as a raw material supplier. Packaging manufacturers require large, consistent volumes of fiber, making this option best suited for industrial-scale juicing operations or cooperatives.

Operational Logistics: Storage and Handling

Managing bagasse on-site before disposal requires strict protocols to maintain hygiene and safety.

Moisture Control

Wet bagasse (above 50% moisture) begins to ferment within hours in warm climates. This fermentation produces sour odors, attracts flies, and generates heat that can pose a combustion risk in large piles. Investing in a secondary press or dewatering screw can reduce moisture content, stabilizing the material for transport.

Storage Protocols

If bagasse cannot be removed daily, follow these storage guidelines:

- Ventilation: Store in well-ventilated, covered areas to prevent rain absorption and allow heat dissipation.

- Containerization: Use breathable bulk bags or dedicated skips rather than sealed plastic, which accelerates anaerobic fermentation and foul odors.

- First-In, First-Out (FIFO): Ensure older waste is removed first to prevent deep-pile rot.

Building a Circular Waste Strategy

Transitioning from “dumping” to “managing” requires a strategic approach.

- Audit Your Volume: Calculate your weekly tonnage. Farms may want 500kg/week, while biomass plants might require 5 tons minimum.

- Identify Local Partners: Map out nearby composting facilities, cattle farms, and biomass aggregators. Transport costs often dictate the feasibility of the partnership.

- Negotiate Terms: In many cases, the goal is cost-neutral disposal (the partner picks it up for free). For high-quality, dry fiber in large volumes, revenue sharing may be possible.

Frequently Asked Questions

How long can I store bagasse before it spoils?

Fresh bagasse begins to sour within 12 to 24 hours depending on ambient temperature. If dried to below 20% moisture, it can be stored for months. For wet bagasse, daily removal is recommended to maintain sanitary conditions.

Does bagasse require special treatment before composting?

Yes. Because it is high in carbon and tough fiber, it decomposes slowly on its own. It should be shredded and mixed with nitrogen-rich materials to accelerate the breakdown process.

Can I burn bagasse in a standard incinerator?

No. Bagasse has high moisture content which leads to inefficient combustion and heavy smoke. It requires specialized industrial boilers or pre-drying to be burned cleanly and efficiently.

Is bagasse packaging truly biodegradable?

Yes, standard bagasse packaging is fully compostable and typically breaks down within 60-90 days in commercial composting facilities, making it a superior alternative to polystyrene.

Next Steps for Sustainable Operations

Efficient bagasse management starts with efficient extraction. Reducing the moisture content of your waste at the source lowers disposal weight and increases the value of the fiber for recyclers.

Ready to optimize your production line? Request a quote or contact our team to discuss high-efficiency equipment solutions that support your sustainability goals.