In the competitive landscape of food and beverage retail, the sensory experience of a customer extends far beyond taste. While the freshness of the juice is paramount, the auditory environment of your establishment plays a crucial role in customer retention and brand perception. For indoor juice stations located in premium environments—such as hotel lobbies, high-end shopping malls, corporate cafeterias, and boutique cafes—noise control is not merely a luxury; it is an operational necessity.

Industrial juicing equipment, particularly heavy-duty machines like sugarcane pressers, has historically been associated with high decibel levels. However, modern engineering has shifted this paradigm. This article explores why low-noise operation is a critical specification for B2B buyers and how silent engineering directly impacts profitability and operational flexibility.

The Acoustic Footprint of Indoor Juice Stations

When selecting equipment for an enclosed space, the “acoustic footprint” is just as important as the physical footprint. In open-air street markets, the noise of a crushing mechanism dissipates into the ambient traffic sounds. In an enclosed indoor setting, however, sound reverberates off hard surfaces (glass, tile, concrete), amplifying the noise and creating an uncomfortable environment.

The Lombard Effect in Retail

High noise levels trigger the “Lombard Effect,” a psycho-acoustic phenomenon where speakers involuntarily increase their voice pitch and volume to be heard over background noise. If a juice machine operates at 85-90 dB (comparable to a lawnmower), staff and customers must shout to communicate orders. This creates a chaotic atmosphere that discourages customers from lingering and degrades the perceived quality of the establishment.

Target Decibel Levels:

- 40-50 dB: Library or quiet office. Ideal for hotel lobbies.

- 60-70 dB: Normal conversation. The target range for customer-facing equipment.

- 85+ dB: Threshold where prolonged exposure can cause fatigue and hearing damage. Common in older industrial juicers.

Engineering for Silence: Technical Factors

Achieving a quiet sugarcane juicer or low-noise juice machine requires specific engineering choices. When evaluating specifications from manufacturers, buyers should look for the following design elements that contribute to sound reduction.

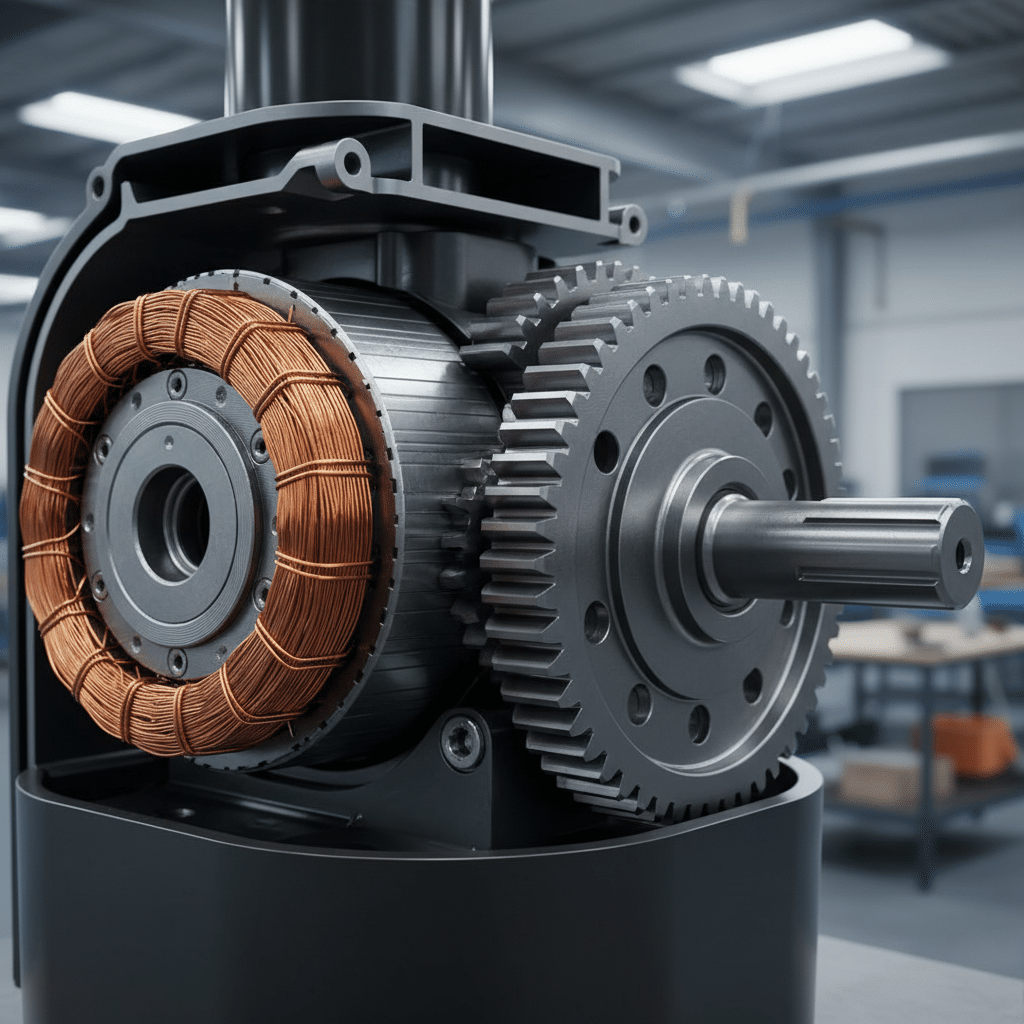

1. High-Torque, Low-Speed Motors

Noise often correlates with RPM (Revolutions Per Minute). Universal motors running at high speeds generate a high-pitched whine. In contrast, induction motors or gear-reduction motors designed for high torque and low speed operate much more quietly. They rely on crushing force rather than centrifugal speed, significantly lowering the decibel output while maintaining extraction efficiency.

2. Precision Gearboxes

The grinding sound often associated with juicers usually stems from the gearbox. High-quality machines utilize precision-machined steel gears submerged in oil baths or sealed lubrication systems. This reduces friction and the metal-on-metal grinding noise that characterizes cheaper equipment.

3. Vibration Dampening and Chassis Construction

Sound is vibration. Machines constructed with thin sheet metal tend to rattle under load. Superior low-noise units feature heavy-duty stainless steel chassis and solid base plates that absorb vibration. Look for units equipped with rubberized mounting feet and internal insulation that isolates the motor from the outer housing.

Operational Benefits of Low-Noise Equipment

Investing in quiet equipment offers tangible ROI beyond just “ambiance.” It affects where you can operate and how your staff performs.

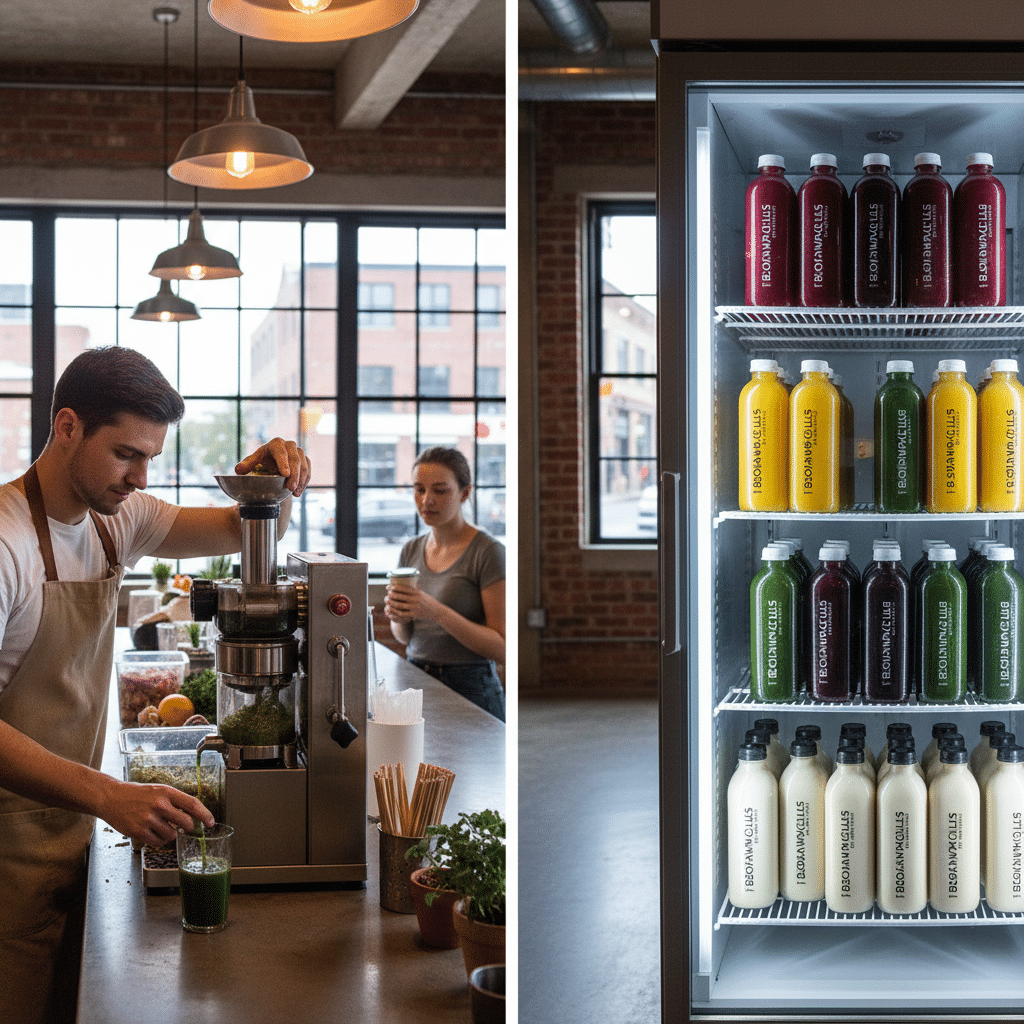

Expanded Placement Opportunities

A quiet machine allows for “front-of-house” theater. You can place the juicer directly on the counter, allowing customers to watch the fresh extraction process without their conversation being interrupted. This is particularly critical for:

- Hotel Lobbies: Where guests expect a serene check-in or lounge experience.

- Corporate Offices: Where noise cannot disrupt nearby meetings or workflow.

- Spas and Wellness Centers: Where tranquility is the core product.

Staff Health and Efficiency

Chronic exposure to noise creates fatigue and stress for employees. By reducing the ambient noise floor, you improve the working conditions for your staff. Furthermore, lower noise levels reduce order errors, as staff can clearly hear customer requests without shouting.

Comparison: Standard vs. Low-Noise Juice Machines

When procuring equipment, it is helpful to compare standard industrial options against modern low-noise variants.

| Feature | Standard Industrial Juicer | Low-Noise / Silent Juicer |

|---|---|---|

| Average Noise Level | 80 dB – 95 dB | 60 dB – 70 dB |

| Motor Type | High-speed Universal | Low-speed Induction / Geared |

| Vibration | High (requires bolting down) | Low (stable on countertop) |

| Customer Interaction | Impossible during operation | Seamless during operation |

| Ideal Location | Back-of-house / Outdoor | Front-of-house / Indoor / Luxury |

Buying Guide: What to Ask Manufacturers

When sourcing a quiet sugarcane juicer or commercial extractor, verify the noise claims with specific questions:

- What is the dB rating under load? Many manufacturers list the noise level when the machine is idling. However, crushing hard fibrous produce like sugarcane increases noise. Ask for data regarding operation under load.

- What materials are used in the housing? Heavier materials (304 stainless steel) generally dampen sound better than plastic or thin aluminum.

- Is the gearbox sealed? Sealed gearboxes generally run quieter and require less maintenance than open gear systems.

FAQs Regarding Low-Noise Juice Stations

Does a quieter machine mean less power?

No. In fact, quiet machines often have higher torque. They achieve extraction through force (gearing down) rather than speed. This often results in higher juice yield and drier pulp compared to noisy, high-speed alternatives.

How can I further reduce noise for my existing station?

If upgrading the machine is not immediately possible, consider placing vibration-dampening mats under the equipment and using acoustic foam panels on nearby walls to reduce echo. However, the most effective solution is addressing the source: the motor and gear mechanism.

Are low-noise machines more expensive to maintain?

Generally, no. The engineering required to make a machine quiet (precision parts, better lubrication, lower RPM) also tends to reduce wear and tear. High-speed vibration is a primary cause of mechanical failure; removing it often extends the equipment’s lifespan.

Is low-noise equipment mandatory for malls?

Many premium shopping centers and mixed-use developments have lease stipulations regarding noise pollution. Exceeding certain decibel limits can result in fines or forced operational changes. Using low-noise equipment ensures compliance with strict tenant guidelines.

Conclusion

For B2B buyers outfitting indoor juice stations, decibel levels are a specification that carries as much weight as yield and hygiene. A quiet sugarcane juicer enhances the customer experience, protects staff well-being, and opens up premium location opportunities that are inaccessible to noisy operations. Prioritizing silent engineering is a strategic investment in your brand’s atmosphere and operational efficiency.

Ready to upgrade your operation? Contact us today to request a quote or discuss technical specifications for our low-noise juice extraction solutions.